Renold to launch new addition to RB product range

Latest rubber-in-compression couplings offer increased safety and higher torque

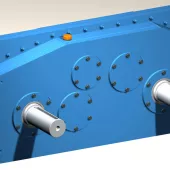

RUBBER-in-compression couplings – such as the new RBI range from Renold Couplings – have been designed to provide failsafe operation, protecting both staff and machinery. Developed for industrial applications, the latest range is said to be the next phase in rubber-in-compression couplings.

Torque is transmitted through compressed rubber blocks, which dampens vibration and eliminates backlash. According to Renold, when rubber is loaded in compression, it is inherently stronger than alternative options, such as rubber-in-shear, or tension, where the slightest scratch in the rubber can lead to catastrophic tears and complete coupling failure – resulting in downtime in both machinery and productivity.

In addition to the safety and reliability features, rubber-in-compression couplings reduce time and costs in term of maintenance. For example, Renold’s RBI range does not require lubrication or adjustment of any kind, and the only serviceable items are the rubber blocks, which in the majority of cases are reliable for 10-plus years (although it is recommended to check them after five years).

Rubber-in-compression couplings, therefore, provide some of the lowest lifetime costs, when compared to other coupling alternatives. Renold’s highly experienced team of engineers worked rigorously in order to completely reconfigure the profile of the compressed rubber blocks, with the ultimate objective of increasing the torque currently offered by the RB.

Finite Element Analysis (FEA) was conducted to create an optimum shape for the rubber blocks, to increase the torque transmission that could be produced when compared to the existing RB rubber-in-compression coupling. Renold say this new block shape is manufactured from a new rubber compound, which is the new standard in the RBI coupling.

The FEA also indicated the combination of this new block profile and new rubber compound, would deliver higher torque. Subsequent testing of the new RBI has confirmed the findings of the analysis and the torque rating has been increased by 50%, when compared to its RB predecessor.