Custom gear units for log-washers

Renold Gears design bespoke solution for manufacturer of heavy-duty coarse-material log-washers

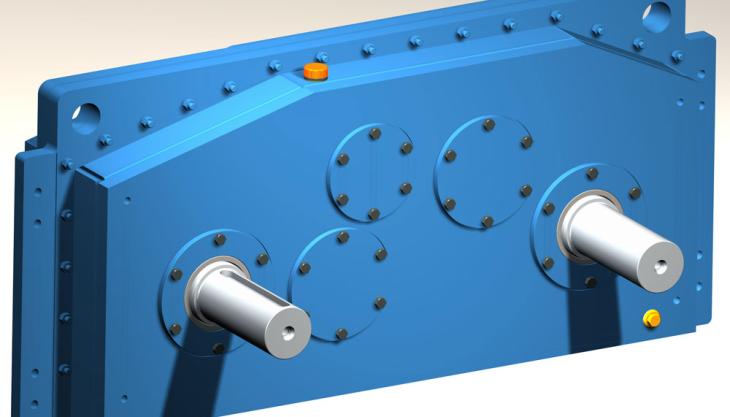

RENOLD Gears have designed a heavy-duty, custom gearbox solution for a manufacturer of coarse-material log-washers.

These rectangular boxes or troughs, which are usually fabricated from steel plate and contain two steel shafts with paddles attached along their length, are commonly used for washing and sizing clay-bound aggregates, gravel, limestone etc.

Known as log shafts, from which log-washers take their name, the steel shafts are aligned parallel to each other within the box, and as they turn the paddles intermesh. This turning and intermeshing of the paddles facilitates material-on-material cleaning while conveying the material along the length of box to the exit point.

The custom gearbox designed by Renold Gears has a single input shaft with counter-rotating double-output shafts to drive the two logs. The internal gearing is designed to ensure the logs are aligned perfectly and do not come into contact with each other during operation.

As well as providing the torque to drive the machine, the gearbox also acts as a bearing support to carry the two logs shafts. They gear units will be supplied in two sizes to match the centres of the logs and the power of the machine.

Renold Gears have supplied gear units to this industry sector for more than 20 years, and the experience they have gained during this time was a primary reason the company was chosen to provide this solution.

The new gearboxes were amongst the first to be produced on Renold’s new £1.8 million, state-of-the art, Burkhardt + Weber machining centre at their factory in Rochdale.