Flexco acquire SHG Conveyor Control GmbH

Company strengthens smart equipment line-up with Rip Prevent+ AI-powered belt monitoring system

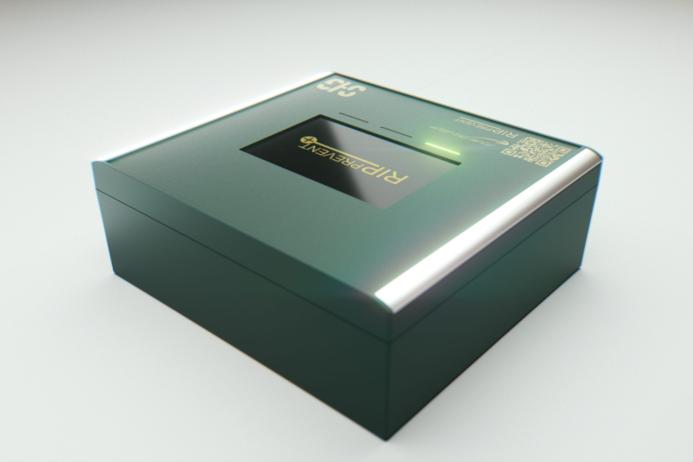

BULK materials handling specialists Flexco have announced the acquisition of SHG Conveyor Control GmbH, the developers of Rip Prevent+, an advanced AI-driven conveyor monitoring system that enhances belt efficiency and uptime.

Rip Prevent+ offers real-time rip detection, prevention, and operational insights without the need for embedded sensors, lasers, or structural modifications. Fully plug-and-play, the system can be installed on any conveyor, delivering instant value for cement, mining, aggregates, and bulk handling operations.

The acquisition further strengthens Flexco’s digital solutions portfolio, combining Rip Prevent with Flexco Elevate, and Novitool Aero splice press with IntelliSplice technology to create a connected, data-driven approach to conveyor management.

Some of the key features of Rip Prevent+ include: instant belt rip and anomaly detection with automatic shutdown; MassFlow monitoring for material flow visualization; optional gearbox and bearing health diagnostics; and motor condition and energy monitoring for improved efficiency.

A Flexco spokesperson commented: ‘The future of conveyor belt management is digital, connected, and data driven. SHG, combined with our Elevate digital platform, will enable us to deliver greater value to customers who rely on us as their partners in productivity.’