All-electric mobile crushing and screening

Kleemann outline the advantages and infrastructure requirements that operators should consider

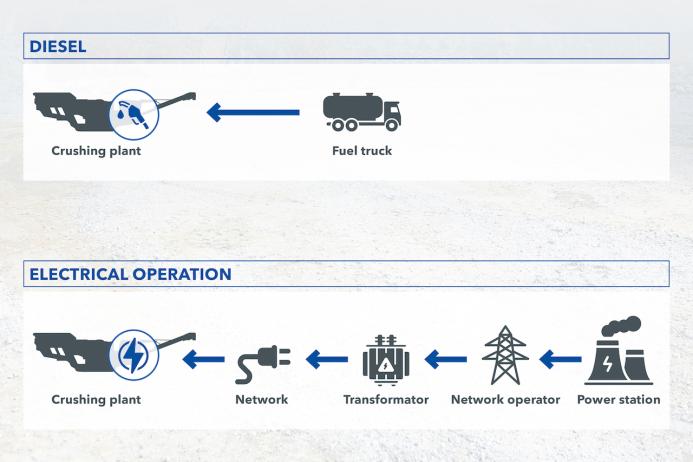

MOBILE crushing and screening plants that are operated with electricity instead of diesel fuel are regarded as particularly environmentally friendly as they do not emit CO2 on site. They are also ahead in terms of cost-effectiveness in the long term.

Sustainable, low-emission solutions are in demand, and companies can position themselves in the market as future-oriented providers with electrically operated mobile plants. Although the initial investment costs are higher, they are quickly amortized due to the fuel savings. A sample calculation for the German market shows that this is already possible after around six years – or even after around four years if the system can be supplied with energy via the customer’s own photovoltaic system.

‘Our mobile plant train in the sample calculation consists of a Mobicat MC 120 jaw crusher PRO, Mobicone MCO 110 PRO secondary cone crusher, and a downstream Mobiscreen MSC 953 EVO screening machine,’ said Tobias Böckle, head of product management at Kleemann. ‘The plant train consumes an average of approximately 77 litres of diesel per operating hour. The electrified version has an average current consumption of 302kW per operating hour and the maximum power requirement is 542kW,’ he explained.

‘The energy requirement must first be provided by the infrastructure and is ideally met by electricity from renewable sources. A sustainable and quickly cost-efficient solution is to use an in-house photovoltaic (PV) power supply.’

A suitable design of the infrastructure in advance is of decisive importance for efficient use, as Tobias Möß from Wolff & Müller GmbH explained: ‘First, the actual energy requirements of the mobile plant and the demand of all other existing consumers should be determined. How much power is needed on the entire company premises? The load profile must also be taken into account. When are the power peaks and when are the times with lower consumption? The individual load profile can be obtained from the energy supplier or network operator.

‘Many companies already have a transformer at their premises that adapts the voltage to requirements, for example, to provide for low-voltage systems. Once the required power has been calculated, it is necessary to check whether the available transformer is sufficiently dimensioned. Does it deliver the required power? The amount of power that can be drawn from the transformer is indicated on the type plate.

‘It is also important to consider where the main distribution point is located on the site and where the system will be used. Good planning here is a precondition for efficient operation. For example, the electrical energy required to supply the plant need not be transformed to low voltage directly at the transfer station, but instead can be routed over the medium-voltage level across the site to the mobile plant – the cable cross-section can therefore be much thinner, making the cable easier to handle and significantly cheaper.

‘At the mobile plant, a second transformer converts the current to low voltage in order to operate the mobile crushing or screening plant. The aim here is to develop a suitable individual concept. With a solid foundation, the investment costs are amortized after around six years – or even sooner, depending on the energy concept. From this point on, all-electric operation will save considerable operating costs year after year.’

Tobias Böckle is convinced. He said: ‘Especially in combination with your own PV system, electrical operation becomes a climate-friendly, cost-efficient concept in just a few years, which not only provides the operating company with financial benefits, but also reflects the company’s efforts to achieve greater sustainability.’