Increased screen media longevity

Haver & Boecker say their Ty-Max and Ty-Wire products are proving more durable than expected

ACCORDING to Haver & Boecker, extensive field tests have proven that their Ty-Max and Ty-Wire polyurethane screen media are offering longer wear life than expected.

‘Product testing is an ongoing process conducted to ensure products are not only meeting customer expectations, but exceeding them,’ said Karen Thompson, president of Haver & Boecker Canada president.

‘Through rigorous testing in the field, we discovered these products are proving to be even more durable than originally anticipated, leading to fewer screen change-outs, less downtime and longer wear life.’

According to Haver & Boecker, Ty-Max lasts seven to nine times longer than traditional woven wire cloth, whilst Ty-Wire lasts four to seven times longer. Each is poured open cast, allowing the screen media to harden when cured to resist wear and tear, offering one-and-a-half to two times longer wear life over injection-molded products.

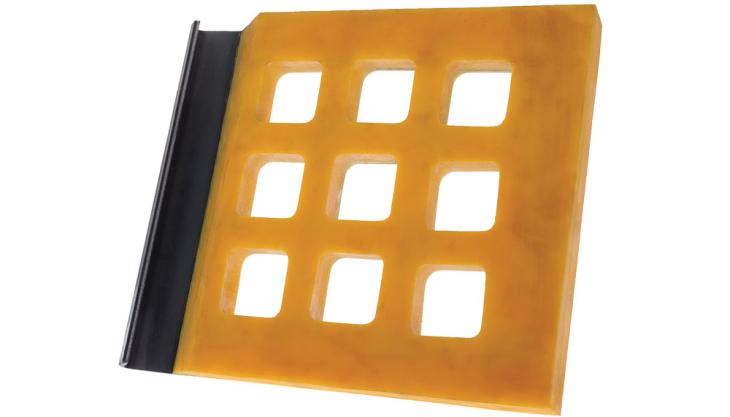

The company says producers often choose Ty-Max when they are looking for more wear life on side-tensioned screen decks. Because it is side-tensioned instead of modular, it can be combined with other side-tensioned screen media on a cambered deck to create the optimal balance between wear life and open area. Ty-Max openings range from 3/32in to 4in.

Ty-Wire – a hybrid between polyurethane and woven wire – is available with openings ranging from 1/8in to 1 5/8in. Low-maintenance and lightweight qualities make Ty-Wire safer and easier to install than traditional woven wire, and it offers greater open area than polyurethane. It is available in both side-tensioned sections and modular panels.

Both Ty-Max and Ty-Wire feature a tapered opening design that releases more near-sized material, allowing the screen to self-clean.

Typically, a switch from woven wire cloth, which requires a cambered deck, to a polyurethane modular product requires a costly deck conversion. However, with Ty-Max and Ty-Wire, Haver & Boecker say producers can switch to polyurethane or a hybrid screen media without the added expense of converting their cambered deck.

Additionally, the company’s certified sales team works directly with aggregates operators to determine the best screen media combination for each unique application. Ty-Max and Ty-Wire can be blended with perforated plate, rubber, woven wire or self-cleaning screens to extend wear life and improve performance of the screen media overall.

For example, a section of Ty-Max at the feed end can help alleviate the additional wear that comes with the initial material impact, whilst Ty-Wire can be used in the middle of the deck, where basic screening takes place, to give operators the optimum combination of wear life and open area. Woven wire or self-cleaning screens at the discharge end will provide maximum open area at the end of the deck.