Construction to start on Padeswood CCS project

Heidelberg Materials and the UK Government reach FID to build the world-leading carbon capture facility

HEIDELBERG Materials are building the world’s first carbon capture facility to enable fully decarbonized cement production after reaching a Final Investment Decision (FID) with the UK Government for their carbon capture and storage (CCS) project in North Wales. The funding decision aligns with the UK Government’s ambitions to reduce CO2 emissions and deliver economic growth through construction.

The announcement, made today by Michael Shanks, Energy Minister in the Department for Energy Security & Net Zero, allows the company to start construction of a carbon capture facility at its Padeswood cement works later this year and will allow production of net-zero cement in 2029.

Simon Willis, chief executive officer of Heidelberg Materials UK, said: ‘Our constructive partnership with the UK Government has allowed us to reach this major milestone, which is fantastic news, not just for us, but for the industry as a whole.

‘Our new facility at Padeswood will be a world-leader. It will capture around 800,000 tonnes of CO2 a year from our existing cement works, allowing us to produce evoZero carbon-captured net-zero cement, which will help the UK construction industry reach its decarbonization aims.

‘CCS is a growing sector worldwide and our Padeswood project is an exemplar, helping position the UK as a global force at the forefront of this technology. It will also pave the way to decarbonizing our domestic cement industry, helping it remain competitive while mitigating against climate change.’

As the CO2 emissions resulting from the chemical process involved in the production of cement cannot be avoided by using low-carbon or renewable energy sources, the only way to remove them and produce the net-zero cement the UK needs is to capture them using CCS before they enter the atmosphere.

The carbon capture facility at Padeswood is designed to capture almost all (c.95%) of the CO2 emissions from the cement manufacturing process. The emissions captured from the kiln include biogenic CO2 from biomass fuels, mainly from domestic food, wood, and paper wastes that cannot be recycled, which could allow the cement produced at Padeswood to be net negative.*

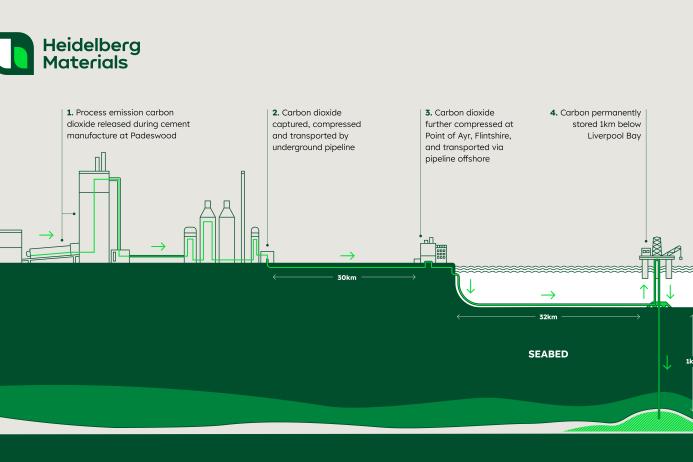

The carbon captured at Padeswood will be compressed and transported via an underground pipeline for secure storage under the seabed in Liverpool Bay as part of the HyNet North West project.

Heidelberg Materials’ CCS project will bring significant economic benefits to North Wales through investment and job creation: it will protect over 200 jobs and create around 50 new ones, as well as up to 500 more during construction.

Energy Minister Michael Shanks said: ‘Our clean-energy mission means good jobs, regional growth, and investment for local communities. This trailblazing cement works showcases the North Wales workforce on the global stage – leading the charge in the clean industries of the future and powering Britain’s reindustrialization through this UK-first project.’

According to Heidelberg Materials, today’s announcement is another demonstration of the company’s commitment to decarbonizing cement production through CCS. The Padeswood project is the first of its kind in the UK and Heidelberg Materials’ first full-scale carbon capture facility to reach FID. It follows the official opening of the world’s first carbon capture facility in June this year at Heidelberg Materials’ Brevik site in Norway, where 50% of the cement plant’s CO2 emissions are being captured as part of the Norwegian Government’s Longship programme.

Commenting on the Padeswood announcement, Dr Dominik von Achten, chairman of the managing board of Heidelberg Materials, said: ‘This milestone comes just a few months after the launch of our Brevik CCS facility. It demonstrates the momentum behind our Net Zero agenda. At Padeswood, we have an invaluable advantage: We’re building on the knowledge and learnings developed at Brevik by working closely with the teams behind its success – sharing best practices with our UK colleagues, whose expertise and enthusiasm will drive the project forward.’

Dr Katharina Beumelburg, chief sustainability and new technologies officer of Heidelberg Materials, commented: ‘Padeswood CCS represents a transformative leap for the entire hard-to-abate sector, both from a technological and a sustainability perspective. With evoZero from Padeswood, we will enable ambitious sustainable construction projects with measurable and verifiable CO2 reductions – driving real change and shaping the future of our built environment.’

Jon Morrish, member of the managing board of Heidelberg Materials and responsible for Europe, added: ‘The UK Government has created a strong and supportive framework for industrial decarbonization, which should serve as a blueprint for other countries in Europe. We applaud its commitment to helping de-risk and enable a successful business case for projects like Padeswood CCS. It will be our second plant in Europe to produce evoZero carbon-captured net-zero cement, helping our customers and the wider construction industry achieve their climate targets.’

Also commenting on today’s announcement, Dr Diana Casey, executive director for energy and climate change, cement and lime, at the Mineral Products Association, said: ‘The green light for the UK’s first carbon capture-enabled cement plant at Padeswood is a landmark step on the road to decarbonizing our domestic cement industry – it will safeguard existing skilled jobs and create new opportunities too.

‘Public investment in this project provides a strong vote of confidence in the technology and recognizes the vital role cement plays in supporting economic growth while delivering on the transition to net zero. Decarbonizing heavy industry is not only essential for meeting climate goals, but also for securing the future of communities across the country – today’s announcement delivers on both.’

*Biomass is carbon neutral as trees and crops remove CO2 from the atmosphere as they grow by storing it within their cells. Any CO2 released from these materials in the kiln would also be captured by the carbon capture facility. As a result, the capture of biogenic CO2 could allow the cement produced at Padeswood to be net negative.