Total Drive Solutions from DESCH

First published in the September 2018 issue of Quarry Management as Total Drive Solutions

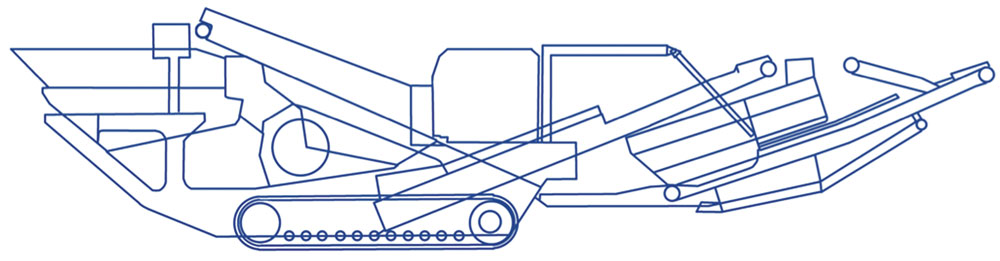

David Cull, technical sales engineer with DESCH Antriebstechnik GmbH & Co.KG, outlines the company’s total drive solutions for mobile crushers

Mobile crushing is one of the most demanding applications with regard to the transmission of power from the prime mover (engine) to the driven chamber (crusher), with a range of small and large mass moments of inertia involved in different crushing applications.

Due to increasing demands to make mobile machines smaller and lighter to meet international road transport laws, original equipment manufacturers (OEMs) have been striving to make the most efficient mobile machine in all aspects – from size and performance to fuel efficiency, and all whilst meeting the requirements of strict emissions laws in effect worldwide. Gone are the days of adding extra power just because you can – which means the balance has to be just right.

Revox – innovative design

As experts in driveline technology for more than 100 years, DESCH have operations across eight countries and the company’s products are found in machines worldwide.

Specializing in the clutch and brake industry, over the last 10 years DESCH have been working closely with OEM customers in the mobile crushing industry to understand their needs and learn what they would like to see available in the market. This close collaboration has led to the development of the Revox gearbox/clutch combination range, which has been designed and built to meet the particular demands and needs of the mobile crushing market. It has proven to be a popular choice among some of the largest mobile crusher OEMs in the world, delivering an innovative and reliable driveline solution.

In order to create a product that was not only capable of fulfilling the demanding applications of the mobile crushing industry, but was also able to operate reliably across the globe in both the coldest weather and the hottest, whilst covering different power and torque range capabilities, DESCH first had to design the wet running clutch to use as their foundation. From here, they had a number of additional design principles to consider:

Size – Make the clutch too big and there was a risk it would not fit in the customer’s powerpack; too small and the new modern diesel engine torque range might be higher than the clutch could transmit. Getting this balance right results in a clutch that can be used in more than one application – getting it wrong means having to design a different product for every power and torque option available today (ie hundreds).

Clutch engagement – The next hurdle is in designing how to engage the clutch safely and in a controlled sequence. Using hybrid technology to get the driven mass up to equal speed with the diesel engine’s selected idle speed allows the engagement to be precise and controlled with little or no slippage or heat transfer to the lubricating oil. Furthermore, combining a hydraulic start-up motor and wet running clutch to achieve a complete engagement from zero rev/min to full working speed removes the risk of damage due to operator error and also reduces any normal wear that would have been associated with conventional clutch packs, thus making this now a virtually wear-free operation.

To do this, one option would have been to select a large enough hydraulic motor, but this would have resulted in the machine effectively being as expensive as a hydrostatic drive machine, along with the costs of a wet running clutch direct-drive solution. However, thanks to superior knowledge and experience, and by selecting the right ratio, DESCH have been able to use a small hydraulic motor to turn a large amount of inertia using only small volumes of oil – something that is easily available on today’s mobile crushers and, therefore, provides a cost-effective solution to the problem.

PTO requirement – Last but not least, DESCH listened to customer requests for power take-offs (PTOs) to allow the connection of hydraulic pumps to supply the rest of the auxiliary functions on mobile machines, with the added requirement that these PTOs have a speed increase to allow maximum flow at lower engine rev/min – this gives the Revox its distinctive look.

Based on the above design, DESCH’s controls team were able to utilize the hydraulic start-up motor to create intuitive software that allows the option to reverse the output shaft in the event of a jaw chamber blockage or, as some customers have opted for, to use this feature to position the rotor of an impact crusher in order to change the blow bars safely and efficiently.

Revox S – compact but capable

With the success and positive feedback received from the OEMs and their customers, DESCH decided to create the Revox S – the smaller brother to the proven Revox. Designed for the customer who does not have large PTO requirements for pump drives, it uses all the same technology from the Revox, but incorporated in a compact housing.

The Revox S has proven to be an effective choice for the 9-litre engine market and completes the range of wet running clutches that DESCH offer.

Planox – superior control technology

At Hillhead 2018, DESCH officially launched the Planox SR dry friction clutch, equipped with arguably the most superior controls package available in today’s heavy-duty clutch market. Compatible with J1939 protocol, it allows a simple plug-and-play integration to OEMs’ current machine controls and displays, collecting data during normal operation and allowing the operator to see every detail related to the driveline, from speed and pressures to loads and even historical data. This technology allows service teams to plan maintenance and minimize downtime. Connectivity is made simple via Bluetooth, thus eliminating the need for costly and clumsy diagnostic leads and software. All that is required is a compatible smartphone/device.

Bespoke solutions

DESCH are often approach by customers enquiring about added features and benefits on existing products, even on the control software side. As this is the company’s core business, we understand that what might not be a key feature for one customer may be particularly important for another, and always strive to work closely with customers on bespoke solutions and are willing to design any key request that an individual customer may have, hence the reason the DESCH motto: ‘Total Drive Solutions’. For more information visit: www.desch.com

- Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com