Screen Machine Industries fit curtain relief system to impact crushers

First published in the September 2013 issue of Quarry Management as Lifting the Lid

Addressing a need for safety through productivity

Readers might ask how machine productivity ties into employee safety. Ohio-based Screen Machine Industries (SMI) did ask this question, and worked towards developing US Patent #7,229,041 for a solution. When working around crushing equipment, one of the safest places a person can be is in the operator’s cab. And when looking at what forces an operator to leave the safety of the cab, the age-old practice of manually clearing material blockages from the crusher feed inlet clearly stands at the forefront.

The wide range of mobile plant used to load material into all brands of tracked mobile crushers can routinely deliver oversized, stacked or misaligned material that will clog or bridge the inlet to the crushing chamber and, therefore, need to be cleared. Crushing projects can be brought to a halt by this bridging of material, with production stopped while the crusher rotor and engine shut down to make it safe for personnel with tools to clear the blockage. Typically, pry bars, slings and hydraulic or pneumatic hammers are utilized to free the bridged material so that production can resume. Common to this process is the potential loss of hours of production per episode, along with the loss of hundreds of tonnes of output, depending upon the severity. The safety of site personnel should, of course, be of paramount importance in this situation, along with lost production.

Efforts to avoid the safety concerns and manual labour involved in clearing such blockages can lead to further productivity losses. Loader operators often slow the feed of their crushers to 50-75% of their rated capacity or spend an excessive amount of time pre-breaking the material into smaller sizes in an effort to avoid repeat bridging issues. Both methods significantly slow down production output.

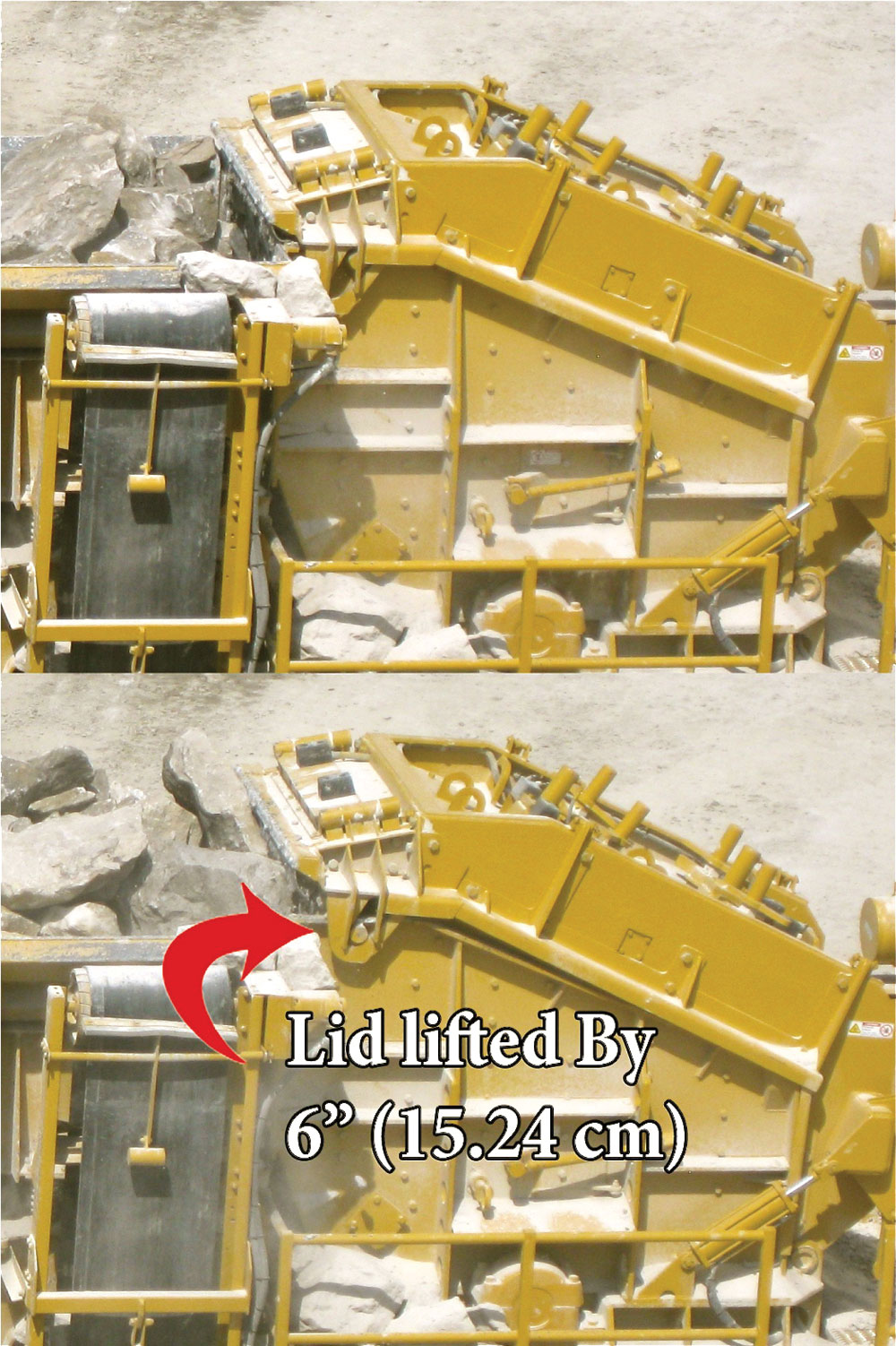

This was the motivation behind the idea to equip SMI’s 5256T and 4043T impact crushers with the capability to remotely raise and lower the entire crusher lid curtain while the machine is in service. The company’s team of engineers designed a remote-controlled pivoting arrangement between the chamber lid and the chamber housing in order to accomplish this. At the push of a button, the lifting lid of the chamber can raise and lower vertically relative to the housing opening without having to shut down the machine.

The curtain relief system creates a temporary increase in height that permits material that has bridged or obstructed the crusher opening to pass freely through the chamber, thereby preventing costly downtime and lost productivity. It also helps to alleviate the fear of material bridging and the need for excessive pre-breaking of the material prior to crushing. The system has been a standard SMI-patented feature since 2007, helping to keep production on task, on time and operators safely inside their cabs. Additional labour costs and downtime are effectively minimized while productivity is enhanced.

Due to the weight and speed of the crusher rotor, it can take around 20 minutes for a crusher to fully ‘wind down’ to a complete stop when shut down. It is not uncommon for it to then take a further 40 minutes (or more) to clear a blockage within the crushing chamber. That is around one hour of downtime for each blockage. Assuming a limestone is being crushed at a rate of 600 tonnes/h and the crushed product is being sold for £5.00 per tonne, a company can lose £3,000 per episode. Even if a blockage occurs just two or three times a day, the company could be left with only five or six hours of actual productive work in an eight-hour day, potentially losing up to £9,000, or more, on a daily basis. However, by utilizing the SMI curtain relief system, at the push of a button most blockages will clear themselves in the time it takes the loader operator to scoop up another bucket load of material to be crushed.

For further information, including a video of an SMI 5256T impact crusher with the remote lifting lid in action, visit: www.screenmachine.com

- Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net