High-efficiency elevator buckets from 4B Braime

First published in the October 2013 issue of Quarry Management as Modern vs Traditional

High-efficiency elevator buckets

An elevator bucket is an elevator bucket, right? Not anymore. Recent advances in design technology have seen the advent of the modern, high-efficiency, centrifugal discharge elevator bucket. High-efficiency elevator buckets push the traditional limits of carrying capacity, input flow and discharge, construction materials and shipping space.

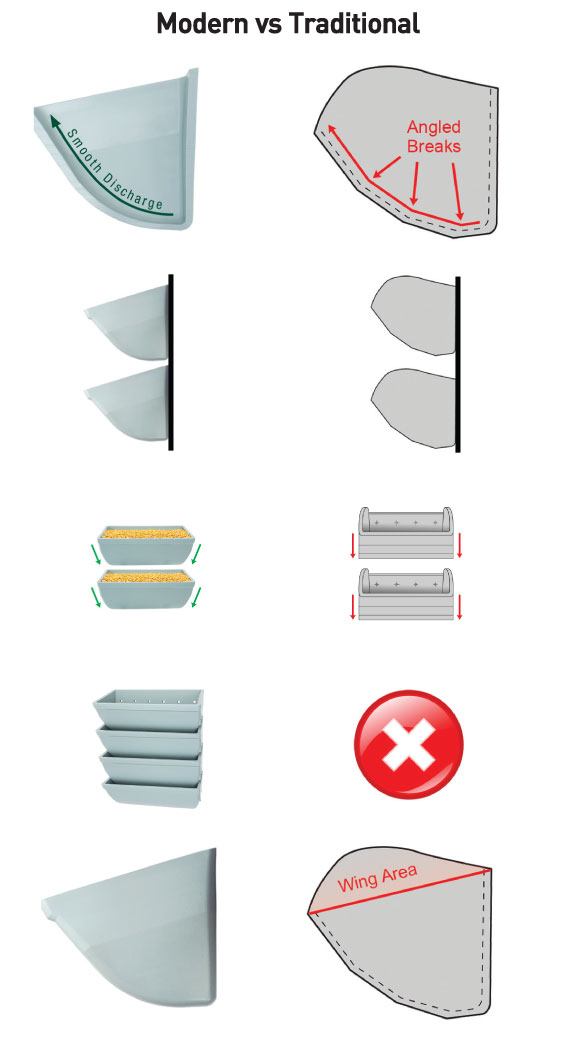

A high-efficiency elevator bucket will have the following characteristics (see fig. 1):

- Smooth interior front faces with no breaks, providing efficient discharge at higher speeds.

- Ability to be mounted close together to deliver the greatest and, thereby, most efficient throughput.

- A tapered bottom that allows the buckets to fill and discharge efficiently, and also allows the buckets to nest inside one another for more efficient shipping and storage.

- Wing-less sidewalls, making the design more cost-efficient through reduced material costs.

The ‘breaks’ or ‘angles’ seen in the interior front face of some traditional elevator buckets serve no determinable function. They neither improve material flow nor discharge efficiency. They simply mimic the design employed by the original fabricated steel buckets of the 1920s, where a break press was used on sheet steel to gradually bend the metal into a curve.

High-efficiency elevator buckets have a smooth interior front face employing compound curve geometry. This delivers an efficient discharge with no impediments and no crevices where product can collect. Thus, clean-out is efficient and cross-contamination is minimized.

High-efficiency elevator buckets also feature a tapered bottom. This is key to the performance of the high-efficiency design and is leveraged for several advantages. It allows the buckets to be mounted closely together with a minimum of vertical spacing. This creates a ‘column’ of input material and generates the greatest amount of throughput possible in the elevator leg system.

Close vertical spacing requires the efficient entry and exit of input materials into the elevator bucket string. The tapered bottom allows the buckets to fill and discharge not just from the front, but from the sides as well. This style of bucket feeds more efficiently on the up-leg, but also in the boot section too.

Moreover, the tapered bottom allows high-efficiency elevator buckets to ‘nest’ inside one another, making shipping and storage more efficient. Traditional buckets do not nest and, even when packaged to minimize space, it is mostly air that is being transported. A stack of high-efficiency buckets is more dense and, as such, qualifies for the most economical freight rates. Additionally, they take up less space in the motor trailer or shipping container, thereby reducing costs even further. Once at the job site, they occupy less floor space for storage.

The ‘wings’ or ‘ears’ found on some traditional elevator buckets do not serve any determinable function. The origin of the feature is unclear but appears to originate with the first fabricated sheet-steel buckets of the 1920s, where it may have served as a handle for shop welders to safely grab with their fingers as they tack welded the inside of the buckets.

There is no evidence that the wing provides extra guidance for material during fill or discharge. Moreover, buckets with this feature cannot be nested for shipping and storage. High-efficiency elevator buckets do not have wings or ears, thereby allowing material cost-efficiencies and, in some cases, weight savings to be realized.

The advent of the modern, high-efficiency, centrifugal discharge elevator bucket has brought industry greater throughputs and cost savings. Now popular in agricultural applications, they are also becoming more widely accepted for industrial use, where oversized, slower moving elevator buckets have often been utilized.

A true high-efficiency elevator bucket (see fig. 2) has a smooth interior front face, can be mounted closely together, has a tapered bottom, can nest inside another bucket and has no wings on the sidewalls.

For further information visit: www.go4B.com

- Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net