Blasting, loading, hauling

First published in the December 2025 issue of Quarry Management

Operating together to deliver optimized results

With advances in drilling and blasting technology working to improve the entire face-to-gate or mine-to-mill process, in this article EPC-UK commercial manager Ryan Ward talks about the positive impact that effective, digitally supported drilling and blasting can have on loading and hauling performance.

Digitalized developments

‘Over the past decade, there’s been an increased focus on developing digitalized techniques to optimize blasting practices. These, in turn, have helped to improve efficiencies and generate more value at the load and haul stage,’ said Mr Ward.

‘New software and solutions that have been introduced to the market are allowing EPC-UK’s engineers to achieve greater accuracy and control for customers in terms of blast performance, fragmentation control, and distribution. As a result, we’re now able to design blasts that specifically suit loading and hauling efficiency as well as crushing performance, which means we can target sizing within a distribution for customers who want to maximize their load and haul outcomes.

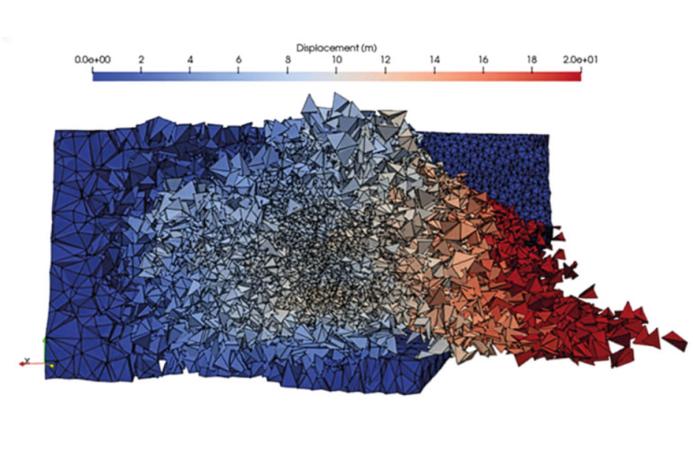

‘We do this by using fragmentation cameras on crushing kit and applying data from drone flight surveying to analyse rockpile throw and swell factors. The data we gather is then fed into computerized software with a continual feedback loop in the dashboard. It can include live data supplied by load and haul contractors’ systems. From the dashboard, our engineers can analyse the data and make improvements to the next blast design to continually optimize loading and haulage performance. In addition, our operators use electronic detonators, as well as their expertise in accurate hole placement, to blast different geologies more effectively, which helps to deliver targeted and desired rockpile shapes that better suit the loading equipment that customers have on site.’

Optimized improvements

‘The combined use of all these tools not only benefits the blast, but also loading, hauling, and crushing performances further down the line. Their integration into the process minimizes wear and tear and reduces repair and maintenance costs on loading and hauling plant and machinery. They can also help to increase payloads (volume of rock per truck moved) and reduce loading cycle times and fuel consumption for excavators and loading shovels.’

ROG+: adding value with futureproof capabilities

Key to EPC-UK’s ability to help deliver increasingly optimized load and haul results is their development of the technologically driven Rock on Ground Plus (ROG+) service, which uses digitalized hardware and compatible software to improve the user experience; from adding value and making systems easier to operate and data simpler to export, to providing extra levels of safety and backup, and ensuring futureproof capabilities.

How ROG+ works

ROG+ is an advanced, highly sophisticated, and accurate blasting service developed by EPC-UK and EPC Groupe in which digitally gathered data from sites are used to drive improved blast outcomes. Customers using the service choose only the specific elements they need to support the loading equipment, hauling trucks, and crushing setups they already have on site, helping to improve their entire value chain from face to gate or mine to mill. The service streamlines operations as it makes hole placement extremely accurate and delivers the maximum performance from the explosive product used.

The impact of each blast on all downstream equipment and processes is assessed in a continual feedback loop, making it possible to see how blasting activities are impacting the customer’s overall quarrying operation, as well as the performance and value gained from the materials that are being extracted. The data reviewed by all on-site parties is inputted back into the next blast decision with slight adjustments made each time. This allows customers’ operations to progressively become more optimized, and for loading, hauling, and crushing operations to generate maximum efficiencies and operational value.

Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com