Viby Attachment add value through innovation at Hillhead 2014

Viby Attachment used Hillhead 2014 to show why their growing reputation for innovation and improvement is fast matching their ongoing reputation for quality and durability.

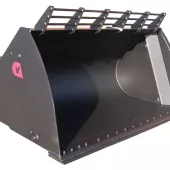

The Danish bucket manufacturer showcased a number of products that are already very popular in the UK, such as its Hy-Tip buckets, as well as products which have traditionally been more popular in mainland Europe, such as excavator buckets (pictured).

But it was the number of new technical developments, both large and small, which helped to define Viby at Hillhead 2014.

Andrew Little, director of Viby Attachment (UK) Ltd, said: ‘Hillhead fell at just the right time for us to showcase some fantastic improvements to our range. A number of these innovations have the ability to add real tangible value for customers.

‘We’ve particularly striven to make improvements that directly benefit a customer’s bottom line, whether it’s in terms of fuel savings, time savings, greater productivity or reduced downtime. Hillhead gave us a timely opportunity to demonstrate this commitment to show that better-quality products like ours can actually save you more money in the long run.’

Examples of these innovations include Viby’s new lubrication system. The company has introduced a single-point lubrication system to reduce downtime and simplify the task of daily greasing.

The system, developed by Viby, means that plant operators now need only to add lubrication to their attachment at one central greasing point rather than at multiple points. The technology ensures that the grease reaches all key areas instantly from this one central point. The innovation is available both as a manual system and an automatic version, which is operated via the machine’s own auto-lubrication system.

Its introduction reduces the time needed for greasing, optimizes the delivery of grease to all critical parts of the attachment in the correct quantities, and improves on-site safety, as manual lubrication can be carried out with the bucket at one ground-level position. This system was fitted to two Hy-Tip buckets on the Viby stand at Hillhead: a 4.5 cubic metre waste Hy-Tip; and a larger 7.0 cubic metre light-duty (green waste) Hy-Tip.

Viby Hy-Tips, which are extremely popular in the UK in waste-transfer stations, timber sites, composting sites and biomass applications, account for around 60% of all attachment sales by Viby in the UK. Their durability, quality and increased dump height generally negate the need for customers to buy larger loaders than they would otherwise need to achieve the same dump height.

Mr Little said: ‘Hy-Tip buckets allow for greater dump height without the sacrifice of increasing machine size. This can be critical when you are dealing with a site which has limited space for machines to manoeuvre.’

At the other end of the machine size scale, Viby showed two excavator buckets on their stand: a general-purpose bucket; and a 2m grading bucket. While these have been available and big-sellers in Denmark and the Nordic markets particularly, Viby have rarely pushed their excavator buckets in the UK until now.

Viby also revealed their new-generation coal bucket at Hillhead for the first time. Improvements have been made to the combination of materials used in both standard and heavy-duty specifications, to provide customers with exceptional productivity benefits.

The new design is lighter than previous coal buckets without any compromise being made to the strength of the product, thereby maximizing fuel efficiency and productivity. The combination of steel types allows the bucket to be flexible but durable, even in the most abrasive of conditions. Moreover, the bucket shape has been adjusted slightly to further improve material fill, retention and flow during the work cycle.

Mr Little concluded: ‘We’ve worked exceptionally hard listening to our customers’ feedback and implementing improvements to various product ranges. We’re more confident than ever that our buckets and other attachments, while at the top end in terms of quality, will provide our customers with greater medium-to-long-term savings than our competitors’ products.’