TWS bring latest technological advancements to market

Company showcases new AggWash 300 wash plant and AquaClear water-treatment system at Hillhead 2018

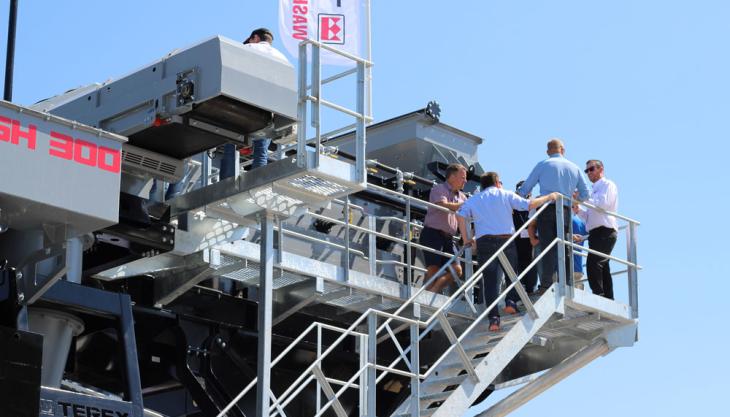

The spotlight was firmly on Terex Washing Systems (TWS) at the recent Hillhead show, with two new products on display – the impressive AggWash 300, a screening, scrubbing, sizing and sand recovery system for recyclable aggregates, all on one modular chassis; and Terex AquaClear, the first water-management treatment system from Terex.

TWS director Oliver Donnelly commented: ‘Terex Washing Systems are focused on bringing to market products that deliver value to our customers and offer solutions that serve their needs. The AggWash 300 and AquaClear we brought to Hillhead do just that. Customers to the stand were excited to see up close these latest innovations and had the opportunity to speak to our technical experts to discuss bespoke solutions for their specific needs.’

The AggWash was designed to address higher production requirements for recycling customers and quarry owners, particularly in the construction, demolition and excavation waste recycling market. The high-performance solution brings together rinsing, screening, scrubbing and sand washing capabilities on a single plant.

While the plant’s readily portable format makes it particularly suitable for greenfield applications, contractor use and temporary planning permission sites, TWS say operators more used to static installations will still appreciate the small footprint and minimal site preparations required.

Commenting on the design, Paul McWilliams, TWS engineer manager, said: ‘In all cases, installation time is significantly less than conventional builds thanks to the high level of factory pre-fitting and connections. The no-compromise design ethos ensures maximum serviceability and performance despite numerous innovative features, including easily removed pumps, ready access to screening media and intuitive controls.’

The AggWash 300 incorporates two 4.9m x 1.5m (16ft x 5ft) triple-deck Terex Cedarapids LJ-TS Series horizontal screens, incorporating a triple-shaft vibrator mechanism that provides high G force along with efficient oval motion. The compact installation height of horizontal screens compared with conventional inclined circular-motion screens is conducive to the condensed working envelope of the AggWash 300, whilst the ‘rolling chutes’ feature provides easy access for screen maintenance.

The machine boasts a high-capacity log-washer with twin-shaft angle adjustment to scrub the gravel fraction and float out organics and adhered contaminants. A 1.8m x 1.2m (6ft x 4ft) trash screen carries out dewatering of lightweight contaminants from the log-washer and the plant has an integrated sand plant incorporating rubber-lined pumps and hydrocyclones, available in various configurations and capacities. Critical for ease of servicing and maintenance, the AggWash 300 also features class-leading walk-around access for maintenance.

TWS also showcased their new AquaClear water-management offering, which allows the company to offer end-to-end solutions for washing and water management from a single supplier. The range includes clarifying tanks, flocculent dosing systems, filter presses and all associated equipment.

The first ever installation is currently being installed in New England, in the US, where TWS are planning an Open Day for customers later in the year. A new dedicated team is in place to lead this aspect of the business, to ensure optimum equipment selection and specification for customers.

Water-management solutions typically consist of three main components: a flocculent dosing plant and thickener tank can be used to recycle up to 80% of the water used in the washing process. This basic method still involves the use of ponds but on a smaller scale, as the sludge sent to the ponds is of a much higher specific gravity (1.5sg). The next stage is to incorporate a filter press, which dewaters this thickened sludge even further, typically down to 25% moisture. The filter press eliminates the need for ponds as the sludge is formed into to a material/cake that can be handled by loading shovel and used as a lining or capping material.

TWS director Oliver Donnelly commented: ‘TWS are due to begin manufacturing the Terex AquaClear water-management solutions in Dungannon, Northern Ireland, later this year, working alongside strategic alliance partners in the US.

‘We are already handling enquiries for AquaClear from Europe and North America. Through our strategic alliance [for North American customers], we can supply a fully built filter press, rather than its component parts in containers. Working with partners who have been in the industry for many years, we are confident that we have the technical capability to devise optimized solutions that will present customers with a unique opportunity to maximize their return on investment.’

Commenting on the Hillhead show, Mr Donnelly said: ‘The reaction to and interest in TWS’s new products and our stand presence was simply overwhelming. The flow of traffic on to the stand was incredible throughout the three days. We had the opportunity to meet with existing satisfied customers, prospective new customers, as well as many of our distributors from around the world.

‘We were delighted to receive a large number of orders throughout the show, which is testament to our commitment to providing enhanced and unique washing solutions to meet customers’ needs and demands.’