Queen’s Award for Hill Engineering

Newry engineering firm receives Queen’s Award for Enterprise in Innovation for its TEFRA coupler

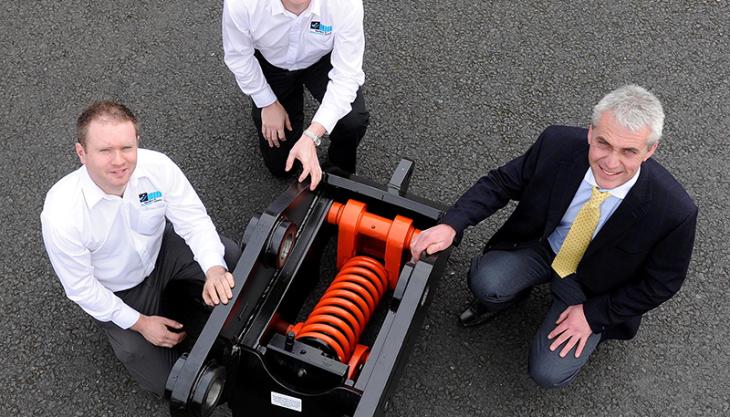

HILL Engineering have been awarded the 2014 Queen’s Award for Enterprise in Innovation in recognition of their TEFRA double-locking hydraulic coupler. The excavator attachment safety system, which is patented by the company and exported across three continents, has been the catalyst for Hill Engineering to double their Newry-based workforce.

Managing director Ian Hill said: ‘Safety is a huge issue on construction sites with numerous fatalities and many serious accidents attributed to the incorrect use of semi-automatic couplers in the UK and Ireland. Our innovative TEFRA, which is fully automatic, has been designed to eliminate such accidents.’

The TEFRA is suitable for excavators ranging from three tonnes up to 120 tonnes and is fully compliant with all expected key provisions of the forthcoming new European (EN474) and proposed global ISO 13031 safety standards.

Since launching the product in 2011, Hill Engineering say they have achieved phenomenal sales in Europe, Australia and US, leading to 30% year-on-year growth for the company. The innovation behind TEFRA is said to lie in its clever and uncomplicated design with only three moving parts.

Engineering manager Neal Loughran explained how the innovation behind the TEFRA technology lies in bringing together five individually engineered elements that each provide their own unique safety features.

‘The two cast coupler hooks have unique ‘curved’ designs that work together to fully enclose both attachment pins providing positive self-locking in all operating conditions,’ he said. ‘This patented load-bearing design has the inherent strength specifically in cast components to take the weight of the attachment in failure mode or if the operator misconnects the rear hook.

‘A single hydraulic cylinder incorporating patented Hill Smart Valve technology operates both hooks, thus eliminating unnecessary complexity and reducing the number of moving parts. There is no external pipework and therefore no risk of damage or failure, and the hydraulic hose connections feature different thread sizes to eliminate the risk of incorrect installation.’

Mr Loughran continued: ‘The Hill Smart Valve is a unique safety feature which prevents attachment removal in unsafe conditions. It works by recognizing the correct/safe coupler orientation before permitting the release sequence to commence. And because the Smart Valve is totally enclosed within the cylinder, it can’t be affected by contamination and requires no routine maintenance.’

TEFRA’s Active Protection System is a fully independent secondary locking system comprising two component parts. A coil spring around the cylinder ensures that the rear hook remains in the correct position in the event of a hydraulic failure, while a leaf spring on the front hook acts to maintain it in the correct position in the event of a hydraulic failure.

These springs do not take the weight of the attachment, which is the job the coupler hooks, but are there solely to keep the hooks correctly located. In addition, the pressure exerted by the springs provides a ‘return to safe’ feature ensuring that the hooks always remain in, or return to, the closed position.

‘This combination of safety features is unique within the attachment industry and provides excavator operators with the safest coupler on the market today,’ said Mr Loughran.