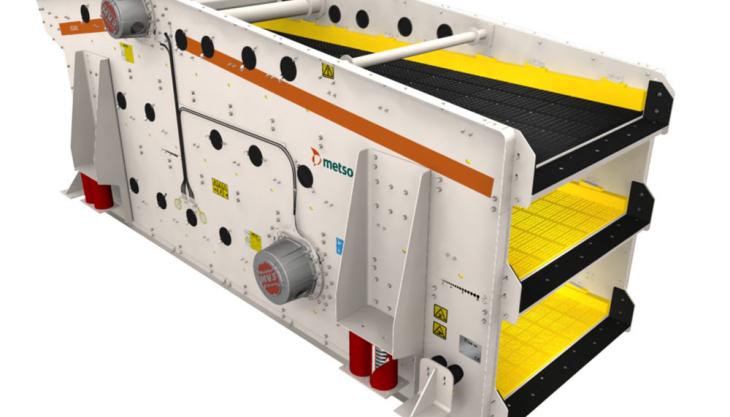

Metso introduce the ES screen

New horizontal screen designed to offer increased uptime and enhanced screening efficiency

METSO are introducing a new, robustly designed, high-energy, elliptical-motion horizontal screen – the Metso ES – which will provide increased uptime and safer maintenance while delivering up to 25% more screening capacity compared with a conventional screen of the same size.

‘Because our customers are aiming for more accurate and consistent material separation with lower operational cost, we have taken the acclaimed Metso modular MV vibrator and integrated it into a unique new screen design,’ explained Mats Dahlberg, global business manager of vibrating equipment with Metso Mining and Construction.

‘Two unbalanced shaft lines in the Metso ES rotate in opposite directions, generating a high-energy elliptical motion with a self-synchronization design. The Metso ES is a unique solution, which performs excellently in any application with high requirements for screening accuracy.

‘Even in difficult screening conditions, such as wet screening or the screening of sticky and dirty materials, the Metso ES provides exactly the kind of aggressive screening action you need,’ he said.

According to Metso, the ES screen features an unprecedentedly robust deck frame design with no welding along the cross-member sections, in order to achieve lasting performance. The weld-free, huck-bolted side plates ensure optimal durability and a high tolerance to stress, while a reliable grease lubrication system keeps downtime and maintenance to a minimum.

For easier, safer and more comfortable access for maintenance, the Metso ES features up to 50% more space between the decks compared with similar flat screens. The screen is also equipped with coil spring covers (to minimize the risk of pinching accidents), rubber stabilizers, belt guards and a single centralized and conveniently located greasing manifold, while the gearless mechanism concept helps to reduce noise.

The screen’s feedbox, discharge spout and cardan shafts feature Trellex modular wear- and impact-resistant rubber linings as standard. Also, Trellex products such as replaceable modular cross-beam protection and LS modular screening media, which are optimized for Metso screens, are readily available as upgrade options for the Metso ES.

The screen’s standard deck frame is preconfigured to handle both modular and tension screen media and can be easily converted to handle the media of choice.

Metso say the ES screen is scheduled to be available in selected markets by the end of May 2013 and will fit together well with their other crushers, feeders and screens as a part of the company’s commitment to offer total crushing and screening solutions.