Bringing digitalized capabilities to sand and gravel operations

As developing technologies and software solutions make quarrying operations leaner and safer, commercial explosives and drilling and blasting innovators EPC-UK detail the value-adding services their digitalized solutions can deliver to improve processes for the sand and gravel sector

EPC-UK are established providers of commercial explosives and drilling and blasting services. The company operates through four divisions: explosives, drilling and blasting, energetics, and logistics. In 2022 it successfully launched its subsidiary company, EPC Metrics, and with it a team of experienced engineering specialists capable of offering technical support and services to improve blasting, site mapping and monitoring within quarrying operations.

‘The technical and consultancy services provided by EPC Metrics are increasing the quality of data available to make informed decisions within the quarrying industry,’ explained commercial manager Ryan Ward. ‘This enables us to support and improve a cross-section of quarrying disciplines, utilizing state-of-the-art drone mapping services, to help sand and gravel production become increasingly efficient. EPC Metrics’ additional specialisms of noise monitoring; vibration-monitoring equipment provision, hire and calibration; and engineering consultancy can also realize a series of problem-solving solutions related to the sand and gravel sector.’

Drone mapping services

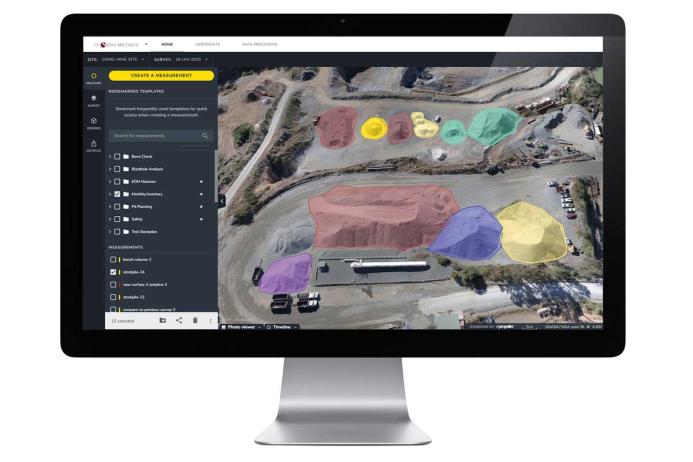

By drone mapping a site and processing gathered data for examination within an interactive software platform, sand and gravel operations can have digitalized access to information detailing their haul road gradients, bund height calculations, stockpile surveys, and volumetric analysis, as well as project tracking.

The data can also be used to conduct safety telematics and ensure compliance, study interactive 3D models, utilize distance and height measurement tools, and support quarry development planning.

‘There are currently 36 Civil Aviation Authority (CAA) qualified drone pilots within the EPC-Metrics team, with the skills to operate drones nationwide, including a WingtraOne Professional vertical take-off and landing (VTOL) fixed-wing drone, from within a modern fleet,’ continued Mr Ward. The drones are used to safely capture data from any area of a quarry, which can then be used, in conjunction with photogrammetric techniques, to create highly accurate, fully geo-referenced 3D models, from face profiles to full quarry maps, which can be regularly recreated as a quarry environment changes.

Remote environmental monitoring

‘The technology we’re bringing to the field is also enabling EPC Metrics to perform fully remote, environmental monitoring on site,’ said Mr Ward. ‘Through our partnerships with leading system manufacturers, we can measure noise, vibration, air over-pressure and environmental conditions. As most drilling and blasting operations must adhere to strict, site-specific planning regulations, including noise restrictions, we’re working to make sure that activities, including those relevant to sand and gravel processes, remain compliant. We use, and can hire out, permanent fixed monitoring stations to gather event data and real-time results in the field. These results can then be fed back to an online platform, reviewed, and analysed, then easily communicated to relevant parties.’

Process in practice

Using their drone technology, EPC Metrics have supported digitalized quarrying processes at several quarries across the UK, recording and analysing the data gathered, and safely optimizing aspects of mineral extraction performance.

By combining advanced photogrammetry techniques and browser-based 3D surveys, EPC Metrics have helped to prioritise the quarries’ operational safety and enhance site efficiencies, development, and mineral extraction planning. By improving data accuracy, using highly detailed imagery from a 42-megapixel camera, advanced data analysis from volumetric cut and fill measurements has been made possible. This has enabled EPC Metrics to progress their work in safety analytics, face height and distance measuring. Furthermore, as the information can be geo-referenced using GPS, EPC Metrics’ surveying practice has been made more accurate, cost-effective, and reliable.

Consultancy support

‘The technology we’re using is supported by our own extensive expertise and knowledge,’ added Mr Ward. ‘It’s providing us with additional skills to optimize operating procedures and problem-solve as well as monitor environmental impact and noise. Add to this our technically enhanced ability to perform more effective safety audits, as well as product development and testing, and we’re demonstrating EPC-UK and EPC Metrics’ success in improving sand and gravel quarrying operations, the digitalized way.’

For more information, visit: www.epc-groupe.co.uk/epc-metrics/

Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com