The Future of Concrete in Sustainable Construction

First published in the December 2017 issue of Quarry Management as The Future is Green

Balancing the need for economic growth with sustainability remains one of the most pressing challenges facing the modern construction world. Cue an abundance of green and renewable technologies, but what are less well known, perhaps, are the advances in the environmental performance of concrete and the impact these will have on the overall green credentials of tomorrow’s buildings. In this article, Donna Hunt, head of sustainability at Aggregate Industries, discusses the latest advancements in ‘green’ concrete and looks at what the future may hold.

All that we build today creates a legacy for the future. Those who design and build our houses, places of work, places of leisure and our infrastructure have a duty to source responsibly the products they use.

According to latest figures, energy from fossil fuels consumed in the construction and operation of buildings accounts for about half of the UK’s carbon dioxide (CO2) emissions, with housing alone accounting for 29%.

To improve the carbon footprint of new buildings, producers and contractors alike are now increasingly being expected to preserve natural resources while continuing to produce quality products, and are, therefore, searching for construction methods, practices and products that will enhance the sustainability of new buildings and infrastructure.

When it comes to concrete – the most widely used construction material in the world, the Government’s plans to invest more than £500 billion in infrastructure coupled with tighter best-practice standards have, in recent years, driven the demand for and advancement of ‘green’ concrete.

The production of cement results in high CO2 emissions. ‘Green’ concrete contains less embodied carbon than conventional concrete. This can be achieved through the absorption of CO2 during the manufacturing process, or through the replacement of some of the cement or aggregates with waste or residual materials, such as ground granulated blast-furnace slag (ggbs) and pulverized fly ash (PFA), making it a more sustainable material choice.

Measuring environmental impact

More recently, Environmental Product Declarations (EPDs) compliant with EN15804 have been introduced to allow building designers, specifiers and contractors to assess the environmental characteristics of concrete. EN15804 sets out the rules for companies to report the life-cycle impacts of products.

With the higher uptake of green building rating systems such as BREEAM, for developers and building specifiers incorporating sustainable concrete into building design starts early, during the planning stages, where the consideration of the life cycle of building materials and their impact on the environment is vital.

Environmental Product Declarations (EPDs)

With improving technology and better product design, suppliers of building materials can now provide clients with detailed information on the environmental impact of concrete as well as customized solutions to reduce it.

For instance, Aggregate Industries recently partnered with BASF Construction Chemicals to create a suite of EPDs for their specialist ready-mixed concrete products: Agilia, Watertight and Diamondcrete.

The EPDs, published by the Institut Bauen und Umwelt (IBU), are based on life-cycle assessment (LCA) calculations using BASF’s life-cycle analyzer tool – technology which allows Aggregate Industries to simultaneously analyse two concrete mix designs to give immediate comparisons of global warming potential (CO2) and 23 other sustainable parameters.

This cradle-to-gate approach looks at the environmental impact of single production units and works well alongside the company’s Product Carbon Footprinting (PCF) tool, developed by the Carbon Trust. The PCF uses mix design, transportation of raw materials and delivery to site to calculate the CO2 emissions of a concrete mix.

EPDs for the full life cycle of a structure or building are also available, based on information supplied by the client rather than generic data (see page 27 for further details).

Customized concrete

As the world’s first construction materials company to achieve BRE BES 6001 – the standard for the responsible sourcing of construction products – Aggregate Industries are leading the way in helping clients to make sustainable design and purchasing decisions by providing third party verified product-specific EPDs.

The development of the BASF life-cycle analyzer tool means the company can vary concrete mix designs and simultaneously compare the impacts of using different constituent materials on both the environment and costs.

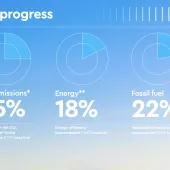

Looking ahead, industry body The Concrete Centre has set ambitious targets to slash concrete CO2 emissions by 30% by 2020 from the 1990 baseline equivalent to a value of 72.2kg of CO2 per tonne of concrete produced.

With manufacturers on track to meet this target, the market for ‘green’ concrete will no doubt gain momentum in the coming years as environmental sustainability, durability and protection continue to top the agendas of construction professionals.

- Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com