Transforming Construction

First published in the March 2023 issue of Quarry Management

Boosting productivity with Continental technology

As the construction industry becomes increasingly digitalized, one key indicator in particular is coming into focus: productivity per construction machine. This is set to rise significantly thanks to automation and the increasing connectivity of intelligent machines, thereby creating more value throughout the construction industry. In parallel with this development, the industry – despite numerous global challenges – is facing a projected doubling of its worldwide business.

‘The construction industry is set to undergo a profound transformation in the coming years,’ said Philip Nelles, chief executive officer of Continental’s ContiTech group sector. ‘We see this market forecast as a great opportunity to further expand our business. Despite the growing demands in the market, we are deliberately focusing on sustainable technologies. And digitalization is also opening up new possibilities for us, which we want to exploit together with the construction industry.

‘On the way to a more efficient, productive and sustainable future, strong partnerships are needed. In this regard, Continental are ideally positioned to support the industry as a reliable innovation partner,’ continued Mr Nelles. ‘As an automotive supplier and technology company, we have set ourselves an ambitious goal. We want to help shape tomorrow’s construction industry today. Thanks to our broad expertise, we are extremely well positioned to realize this technological leap together with the industry.’

Digitalization

The digitalization of products and processes is an indispensable step for the transformation of the industry. At the same time, the requirements for the sustainability and productivity are increasing.

‘Growing demands call for new solutions. For the construction industry, technological innovation and the correct use of materials are critical to success. We are also seeing this in the tyre sector,’ explained Wolfgang Thomale, head of Continental’s speciality tyres business area. With their new LD-Master L5 Traction tyre, Continental are offering their customers and partners an intelligent radial tyre that ensures high traction and safety for loaders with demanding load requirements. The factory-integrated tyre sensor enables real-time monitoring of the tyre.

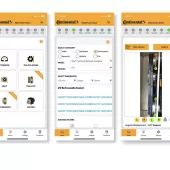

Tyre data, such as air pressure and temperature, are recorded and evaluated with the help of the digital tyre-management system ContiConnect 2.0. If the tyre pressure is too low or there is a risk of overheating, the driver is informed via a warning system. This ensures a failsafe, long tyre life and fuel-efficient operation. Complementing this, the new-generation system also offers the ability to track tyres both in stock and in use, and conveniently monitor them via Bluetooth-connected devices, as well as allowing predictive maintenance.

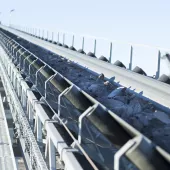

When it comes to conveyor system technologies, the company also offers autonomous end-to-end solutions for more efficient operation in the mining, quarrying and cement industries. The revised Conti+2.0 app-based service platform integrates numerous conveyor monitoring systems and processes in a single application and analyses all important sensor data. This helps companies improve the productivity of their operations and extend the life of their conveyor belts (see article QM March 2023 p28-29).

Connectivity

The digitalization of the construction industry is not only having a positive impact on the sustainability of construction machinery. It is also enhancing the automation and connectivity of technologies, which is having a measurable effect on productivity.

With their new and innovative IoT (Internet of Things) SightIQ solution, Continental say they are setting new standards for productivity management in quarries, mines and construction sites. SightIQ integrates all available data from mobile machines, vehicles and stationary equipment, such as conveyors or tools, in a cloud application, regardless of the manufacturer.

The IoT suite can be expanded to include other digital solutions from Continental, such as Conti+ for intelligent conveyor management or the ContiConnect solution for safe and efficient tyre management. In developing this solution, Continental drew on their cross-industry expertise. ‘We developed SightIQ by combining our knowledge of the construction and mining industries with our expertise in fleet management for trucking companies. SightIQ enables our customers to take an important step towards increasing their profitability,’ explained Ismail Dagli, head of the smart mobility business area at Continental.

Continental are also achieving further innovations by using technology from passenger car development that has been adapted for construction and mining machinery, such as the digital surround view system ProViu 360, one key feature of which is Worker Detection, which allows the system to detect people in close proximity to a construction machine and warn them of collisions, thereby increasing safety in the construction and mining industry.

Another innovation based on a Continental solution for road traffic is the Digital Guardian Angel. In the adaptation of this system for the construction site, people, machines and vehicles are able to communicate with one another via signals that they send via a smartphone or telematics unit. In this way, every machine and every person can be warned in good time of an impending collision.

‘At Continental, we have a clear idea of what the future quarry and construction site will look like. We also understand that change is most likely to succeed through collaboration. With our know-how, we will support the industry on its journey as an innovation partner,’ concluded Philip Nelles.

Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com