New milestone for Lafarge and Solidia

Companies sign agreement to commercialize technology for low-carbon precast concrete

LAFARGE have reached a new milestone in their partnership with US start-up firm Solidia Technologies with the signing of an agreement to commercialize an innovative technology that will allow a significant reduction in the environmental footprint of precast concrete.

The patented technology reduces CO2 emissions in the cement production process and utilizes CO2 in precast concrete manufacturing, reducing the carbon footprint of the end-to-end process by up to 70%.

Under the terms of the agreement, Lafarge will have the right to commercialize this technology worldwide and will offer a complete solution (sustainable cement and CO2-cured concrete) in partnership with Solidia.

The commercial launch will initially take place in some key markets in North America and Europe for the manufacturing of concrete elements such as paving stones, roof tiles and concrete blocks.

Lafarge have been working for more than two decades to reduce their environmental footprint and, in particular, their CO2 emissions, which have been reduced by 26% per tonne of cement since 1990.

Solidia have developed a new binder which is made from similar raw materials to Ordinary Portland Cement (OPC) and produced in a traditional rotary kiln. However, it is produced at lower temperatures and through a different chemical reaction that generates less CO2.

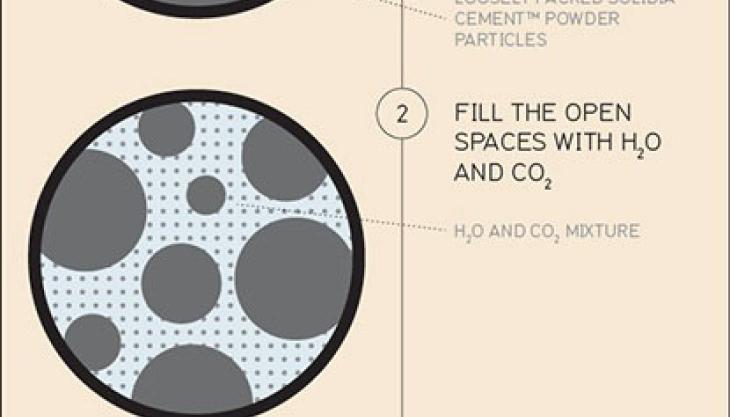

Used afterwards in the manufacture of precast concrete, Solidia cement hardens through the addition and absorption of CO2 (carbonation) in a patented curing process that reduces the overall carbon footprint by up to 70%.

Produced at traditional precast concrete manufacturing facilities, Solidia concrete offers improved performance characteristic and reaches full strength in less than 24 hours, compared with 28 days for precast concrete made using OPC, thus offering considerable energy savings and cost reductions for precast concrete manufacturers.

Lafarge’s researchers and technical experts worked with Solidia to demonstrate the feasibility of commercial-scale production in a conventional cement plant, and in April 2014 a joint group of Lafarge and Solidia scientists validated the reduced carbon footprint and commercial viability of Solidia cement during a full-scale trial at Lafarge’s Whitehall cement plant in the US.

The cement produced was subsequently used by a variety of precast customers in North America and Europe to further validate Solidia’s curing technology and to produce blocks, pavers and roof tiles for commercial testing. These tests are said to have demonstrated both the superior quality of Solidia concrete products and their cost-competitiveness.

Lafarge, who have been collaborating with Solidia Technologies since 2013 in a bid to industrialize this technology, invested in Solidia Technologies and joined the US firm’s board of directors in December 2014.