New Cat technology options for mid-size wheel loaders

Next-generation loaders can now be easily upgraded with fully integrated optional technologies

CATERPILLAR have introduced new technology options for their next-generation mid-size wheel loaders, to advance safety and help customers work faster and with greater accuracy. Fully integrated for optimal performance, Cat 950, 962, 966, 966 XE, 972, 972 XE, 980, 980 XE, 982, and 982 XE wheel loaders can now be easily upgraded with the optional technologies as work demands.

Frank Stadelmann, Caterpillar’s global product application specialist for medium wheel loaders, said: ‘Our new optional Collision Warning system with Motion Inhibit includes Object Detection, People Detection, and Motion Inhibit as a package to improve safe operation by alerting operators and inhibiting loader motion in the instant a machine transitions from an inactive to an active state.

‘The new Cat Payload for Trade* option builds on our Advanced Payload Scale system that electronically captures weight and other data from the loader, now in a certified way, and can send it to the office or directly via email.’

Starting with a foundation of the standard HD rear camera with an integrated touchscreen, Cat medium wheel loaders offer a progressive building block of optional technologies, including the Multiview (360°) Vision System, Rear Object Detection, and now Collision Warning System with Motion Inhibit.

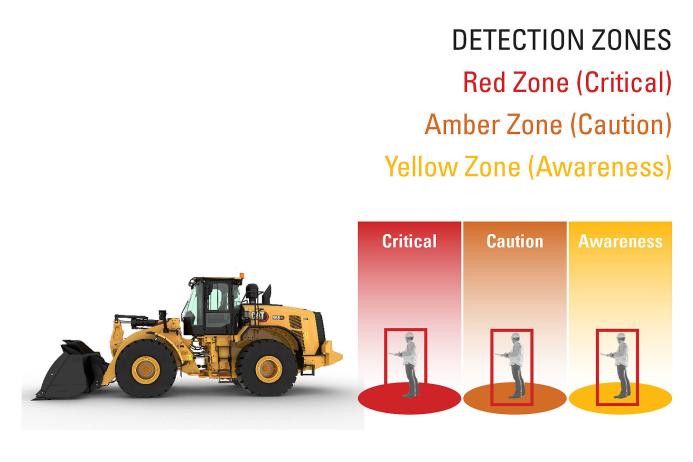

The new system uses radar and vision sensors to detect hazard potential, alert operators, and inhibit motion when initiating reverse motion from a stationary position. Targeting collision potentials that emerge from behind the loader, the Collision Warning System leverages both smart camera and radar technology to give audible and visual alerts to help operators see, mitigate, and manage hazards that might otherwise go unnoticed. The system’s three colour zones – yellow for awareness, amber for caution, and red for critical – approximate the distance of the object to the anticipated path of the loader.

The embedded Motion Inhibit feature prevents direct reverse gear engagement when shifting from neutral and automatically applies the brake when the system detects an object or worker in the critical alarm zone behind the loader. When this occurs, the operator is alerted by an on-screen notification. If the loader is stationary for at least 15s and the operator shifts from park to reverse, Motion Inhibit prevents the machine from engaging reverse when the rear detection system identifies something in the critical alarm zone. The loader will reverse once the operator shifts back into neutral and steers to clear the detection.

People Detection utilizes the smart camera to alert the operator when a person is detected behind the loader. Three levels of alerts dynamically adjust based on the person’s proximity to the machine, and the system highlights people in red bounding boxes on the in-cab monitor to distinguish and manage the potential risk.

Standard Cat Payload for Trade* delivers precise bucket load information with on-the-go weighing to help prevent overloading or underloading. Upgrading to the optional Advanced Payload system expands automation features and capabilities, including automatic tip-off assist for the final bucket process to help precisely meet target payloads, as well as a new multitask mode which tracks two loading processes simultaneously, while split mode allows for loading multiple bodies, tracking individual targets and tabulating grand totals of each load.

From material handling and truck loading to general construction and stockpiling, the integrated Cat medium wheel loader technologies help operators of all skill levels work more efficiently and productively with less fatigue. These new technologies increase the machine’s capabilities by building on a number of standard and optional features already available, including:

Auto set tyres – helps operators with proper digging technique and improves bucket fill factors

Autodig – performs a full dig cycle automatically for the operator upon detecting a dig condition

Programmable kickouts – automates repetitive tilt, lower, and lift functions to reduce operator fatigue

Machine speed limit – offers customers two limit options to control the loader’s top speed

Tyre pressure monitoring system – helps operators to maintain recommended tyre pressure

Remote flash – allows downloaded software updates to be initiated from the on-board display

Remote troubleshoot – remotely connects the loader to the dealer’s service department to quickly and efficiently diagnose fault codes.

Removing the operator from the machine, the recently announced Command for Loading technology offers remote control of next-generation medium wheel loaders. An ergonomic Command console enables line-of-sight remote control of basic machine functions, such as start-up/shutdown, and bucket rack/dump and lift/lower. For non-line-of-sight operation, the Command station can connect to multiple machines and allow the user to operate one machine at a time, either on site or from miles away.

* Available in Europe (country certifications vary)