New C-series jaw crusher from Metso

Metso C120 combines crushing efficiency, versatility and safety in stationary and mobile applications

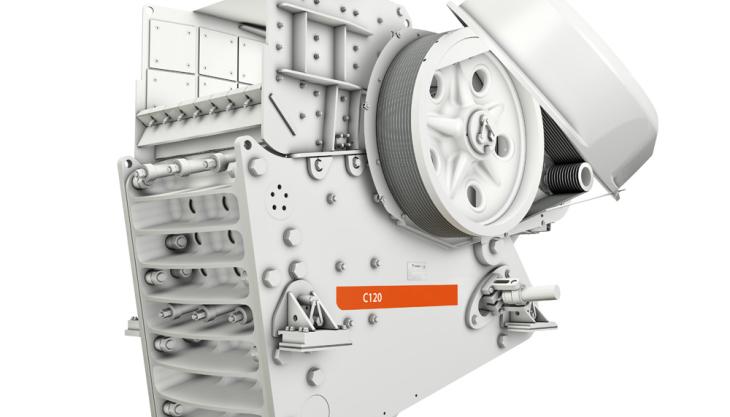

METSO Mining and Construction Technology have introduced the Metso C120 jaw crusher – the 13th unit in the company’s field-proven C-series range of crushers. According to Metso, the new C120 combines reliability, crushing efficiency and versatility in both stationary and mobile applications, with safety and ease of use.

With a durable design based on thorough finite element analysis and casting simulations, Metso say every detail of the user-friendly C120 has been engineered for reliable operation and long life in order to deliver constant and productive crushing capacity and uptime.

‘When starting the C120 project, we listened closely to our customers and collected field data from a number of sites. Based on that, we decided to design the crusher cavity and kinematics first. As a result, we can now offer aggregate producers, large-scale contractors and mining companies a new crusher that meets all the standards set for any demanding application,’ commented Ilkka Somero, Metso’s product manager for jaw crushers.

The C120 – which in terms of cavity volume and crusher weight is positioned between the existing Metso C116 and C125 jaw crusher models – features several new design elements, including a long and aggressively directed stroke, and a fixed jaw die which is longer than previously seen in this crusher size class. It has a large feed opening of 1,200 x 870mm and an aggressive cavity cross-section for optimum performance and maximum reduction ratio.

For a quick, easy and safe setting adjustment, it is possible to select either a mechanical or a hydraulic setting adjustment system, while for jaw dies, several cavity options are available. Depending on the customer’s preference, it is possible to use either single- or two-piece jaw dies.

Weighing 26 tonnes, the C120 has a nominal power of 160kW (200hp), an operating speed of 230 rev/min and a closed-side setting range between 70–200mm. The C120 also features optional robust composite flywheel guards that allow quick and safe access to all service points, and standard delivery includes lifting tools for jaw dies, cheek plates and toggle plate.