Haver & Boecker Niagara in South America

New brand offers efficiency-boosting and resource-saving technologies for South American customers

HAVER & Boecker have introduced their global mineral-processing brand, Haver & Boecker Niagara, in South America. The brand combines the engineering expertise and product portfolios of the company’s three mineral-processing locations in Brazil, Canada and Germany.

Haver & Boecker Niagara combine talents and skills in four major areas: heavy-duty scalping, wide-body screening, washing and pelletizing, all complemented by the company’s signature PROcheck service to help operations maximize profit, productivity and proficiency.

Clayton Carvalho, managing director of the Brazil location, said: ‘Haver & Boecker Niagara has earned the trust and respect of customers in Brazil and across South America with our robust, high-capacity machines, tailor-made solutions and dedicated service. With this unity, we will help our customers reduce resource consumption while maintaining profitability.’

South American-developed technology plays a key part in Haver & Boecker Niagara’s success. One such product is the eccentric vibrating screen, a version of the company’s signature F-Class technology, dedicated for high natural moisture applications. This equipment uses a dry vibratory classification system instead of wet screening to remove fines in high natural moisture situations, reducing water use while increasing production capacity.

The F-Class accomplishes this via an advanced eccentric shaft design, supported by four high-performance spherical roller bearings that allow for a constant amplitude and high specific acceleration; something concentric, two-bearing vibrating screens cannot accomplish.

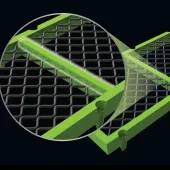

Haver & Boecker Niagara’s new Ty-Deck Ultra is another product that helps reduce or eliminate water use. The polyurethane screen media features a unique H-shaped opening design that increases vibration on the screen deck, improving stratification and reducing the need for a rinsing screen.

The XL-Class is another key Haver & Boecker Niagara technology in South America. The vibrating screen combines advanced exciter drive technology with a wide rectangular or banana-shaped body to offer better screening action and more throughput.

Larger than any other vibrating screen from Haver & Boecker Niagara, the XL-Class is intended for high-tonnage production rates, yet designed for low maintenance, easy operation and unmatched reliability. Traditionally developed for copper and iron ore, the XL-Class is said to suitable for almost any application requiring above-average production rates and/or above-standard process reliability.