Face profiling using 3D images

Blasting Services Ltd have been undertaking trials with a system for generating rock face profiles that employs only images taken with a hand-held digital camera. The BlastMetriX3D system, provided by 3G Software & Measurement GmbH of Austria, consists of a calibrated camera, two calibrated lenses, a series of targets and processing software.

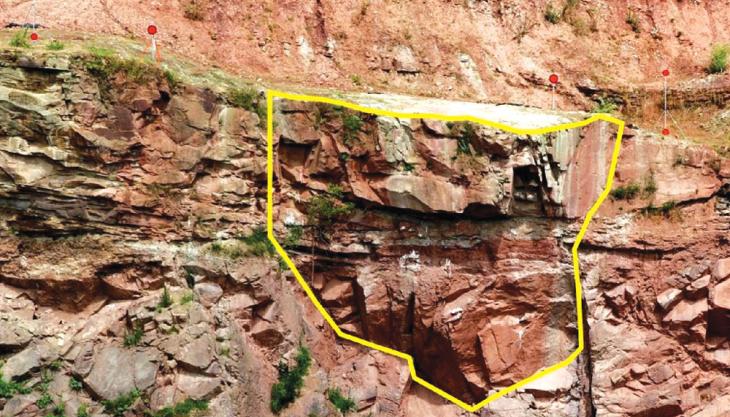

Blasting Services were asked to design and carry out a trimming blast on a rock face relating to a new housing development. The face concerned had an overhang that needed to be removed so that work could safely be carried out underneath. The BlastMetriX3D system was employed for this task as outlined below:

The profiling process comprised the following steps:

The blast was successfully loaded and fired leaving a clean and stable face. There was no projection of the blasted rock greater than 5m from the face line.

From the trial programme it was concluded that: the BlastMetriX3D system provides a simple way of producing a 3D survey of a face and, thereby, profiles suitable for blast design; and a great advantage of the system is that it allows the operator to combine both survey information and images. This allows for the blasthole explosive loading to take into account both burden and geology at the same time.

The system is still under development and does not currently allow for hole deviations to be entered or faces with a free end to be surveyed. However, the software developers are currently working on these issues and Blasting Services say they expect to trial the final system later this year.

Blasting Services Ltd, Venture Crescent, Alfreton, Derbyshire DE55 7RA; tel (01773) 837672.

Blasting Services were asked to design and carry out a trimming blast on a rock face relating to a new housing development. The face concerned had an overhang that needed to be removed so that work could safely be carried out underneath. The BlastMetriX3D system was employed for this task as outlined below:

The profiling process comprised the following steps:

- establishment of reference points: two reference points were established on the bench top to form a line from which the blastholes could be located

- positioning of delimiters: two targets, known as delimiters, were positioned over the reference marks. These targets allow the processing software to locate the ends of the reference line and consist of a single disc on a pole held vertically over the reference mark

- positioning of range poles: the range poles consist of two targets located on a vertical pole. These targets are normally positioned close to the toe of the face but in this case safety considerations meant that they had to be located on the bench top

- taking of photographs: two photographs are required to allow the processing software to produce a three-dimensional image of the face. The distance between the two photographs depends on the distance of the viewing point from the face and should be between one eighth and one-fifth of the viewing distance. In this case the face could only be viewed from about 200m away and a distance of approximately 30m was used

- downloading and processing the photographs: the photographs were downloaded into a laptop and processed via the BlastMetriX3D software. This is a relatively simple process as the software carries out much of the work in a semi-automatic fashion. The output of the software is a 3D model of the face with the actual face image draped over it

- blast design: the included software also allows for the locations of the holes to be entered, relative to the established reference points, along with inclination and depth. In this case a spacing of 1.0m was employed. Profiles were then generated showing both the shape of the face directly in front of the hole and the minimum burden in any direction. The software generates standard profile drawings and the burden information can also be displayed as a colour-coding on the 3D image.

The blast was successfully loaded and fired leaving a clean and stable face. There was no projection of the blasted rock greater than 5m from the face line.

From the trial programme it was concluded that: the BlastMetriX3D system provides a simple way of producing a 3D survey of a face and, thereby, profiles suitable for blast design; and a great advantage of the system is that it allows the operator to combine both survey information and images. This allows for the blasthole explosive loading to take into account both burden and geology at the same time.

The system is still under development and does not currently allow for hole deviations to be entered or faces with a free end to be surveyed. However, the software developers are currently working on these issues and Blasting Services say they expect to trial the final system later this year.

Blasting Services Ltd, Venture Crescent, Alfreton, Derbyshire DE55 7RA; tel (01773) 837672.