Rockit science prolongs component life

Höganäs launches new surface welding powders to help combat effects of impact and abrasive wear

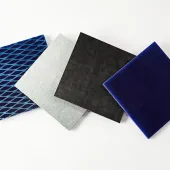

METAL powder specialists Höganäs have launched two new Rockit surface welding powders – Rockit 606 and Rockit 706 – designed to combat impact and abrasive wear to prolong component life in tough wear environments.

‘These materials show excellent performance in challenging applications and overcome the problems of existing industry practices,’ commented Hans Keller, president of the surface and joining technologies product area at Höganäs.

Combatting impact and abrasive wear is a common industry challenge. If components are not protected properly, equipment downtime and short product lifecycles can be costly.

Whereas impact wear resistance as a result of current industry practices tends to be low due to material brittleness, Höganäs say Rockit 606 and 706 feature a special combination of high impact and abrasive wear resistance and are robust enough to withstand process variations.

‘The iron-based materials Rockit 606 and 706 have a martensitic structure with finely dispersed vanadium carbides giving them excellent wear characteristics and a consistent high hardness together with a good impact resistance,’ explained Mr Keller. ‘The materials have excellent welding properties and achieve a smooth deposit.’

Typical applications for Rockit 606 and 706 can be found wherever impact and abrasive wear occurs, such as in the mining, quarrying and construction industries.

‘Rockit 606 and 706 field tests applied on wear plates for dozer blades show that cladding material costs can be reduced by 30%, whilst maintaining the same lifespan achieved with other industry solutions,’ said Martin Lohrman, application specialist at Höganäs ArcX centre in the US.

‘Rockit 606 is recommended for laser cladding, while Rockit 706 is a suitable choice for the plasma transferred arc (PTA) welding process.’

Hans Keller continued: ‘We are building on the success of the previously launched Rockit 401 material, a sustainable solution to replace hard chrome plating. This material has quickly become a standard in the mining and construction industry.’

Rockit is part of Höganäs’ extensive portfolio of surface coating solutions that grew rapidly through Höganäs’ acquisition of H.C. Starck’s Surface Technology division in 2018.

‘As a single, stronger Höganäs organization, we offer a leading portfolio of surface welding, thermal spraying, brazing and welding products to our customers,’ said Mr Keller. ‘With our combined expertise and capabilities, we are in the best position to support our customers, no matter their needs, and jointly solve their challenges.’