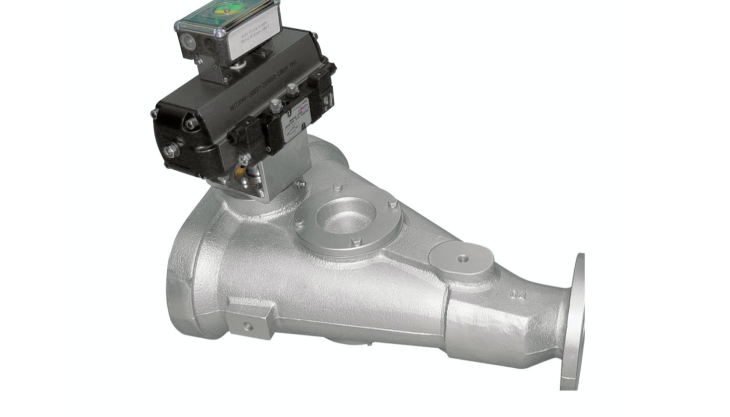

Multi-unit order for BTD ball-type diverter valves

DMN-Westinghouse UK land significant order from major customer in the aggregates sector

AGAINST stiff competition, DMN-Westinghouse UK have recently won a significant order for BTD ball-type diverter valves from a major customer in the aggregates sector.

The BTD was designed specifically to handle abrasive products, such as aggregates in asphalt plants, but BTDs have also been installed as part of systems to handle biomass media and fly-ash in power stations and incinerators.

Elsewhere BTDs have been installed in foundries and cement works and are also used in the glass, ceramic, limestone, gypsum and chemical industries – essentially, just about any industry that processes an abrasive product.

As the BTD was specifically designed to be a part of a pneumatic conveying system, it had to capable of being retrofitted in addition to being installed as part of a brand-new system.

To make the job of both the system designer and maintenance/installation engineer a little easier, the BTD can be installed in a variety of different ways, including vertically.

Once installed, the conditions under which BTD diverters operate are generally harsh, which is why a great deal of consideration was given to maintenance. Consequently, the main seals can be accessed by removing the two side covers while the valve remains in situ.

The housing of the BTD is manufactured from ductile, spheroidal cast iron and, because of the way it has been designed, can handle positive pressures up to 6 bar g and negative pressures up to –0.5 bar g.

Product flowing though the straight leg of the BTD has an uninterrupted flow, but once the valve is set to divert, the product itself provides a wear surface, thereby protecting the valve’s internal components.

The BTD, which can be used for diverting (ie one leg into two) or converging (ie two legs into one) material flow, is available in seven sizes from 65mm to 250mm, and in versions conforming to ATEX 2014/34/EU.