UK Marine Aggregates

First published in the March 2022 issue of Quarry Management

Successfully navigating through an uncertain climate

By Mark Russell, executive director, BMAPA

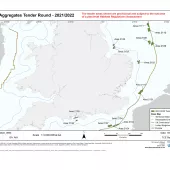

Marine aggregates continue to make a significant contribution to the wider portfolio of construction material supply across Britain, particularly at a regional scale. The latest landing statistics from The Crown Estate, in their capacity as the landowner for majority of the non-energy mineral rights on the UK continental shelf, show that a total of 20.6 million tonnes of marine sand and gravel were extracted from licensed areas distributed in seven geographic regions around the coasts of England and Wales in 2021. Of this, 14.3 million tonnes were landed at wharves in England and Wales for use as construction aggregate, of which 11.3 million tonnes were landed in London and the South East. This is significant, given that one third of all GB construction activity takes place here, representing a value of £57 billion per annum. Elsewhere, marine supplies provide an important role supporting regional construction activity in the North East, the South West, and the North West.

A further 4.3 million tonnes of marine sand and gravel were exported to the near continent for use as concrete aggregate, largely Belgium and the Netherlands, whilst more than 1.3 million tonnes were used to support coastal defence works projects along the Lincolnshire coastline and at Bournemouth, with a further 670,000 tonnes supplied as contract fill to support the construction of the new Everton FC stadium at Bramley Moore Dock, in Liverpool.

Brexit and Covid

The last three years have presented various challenges that have had to be navigated by the British marine aggregate sector. On the one hand there were the changes brought about by the decision to leave the European Union. Historically, 20–30% of marine aggregate production from British waters has been exported to the near continent – particularly northern France, Belgium, and the Netherlands – for use as construction aggregate. Just as in Britain, the ability to land large volumes of marine sand and gravel into coastal urban areas, close to the point of demand, brings significant environmental benefits, both in terms of the emissions per tonne of material landed and the reduction of road miles. But the need for these materials, particularly in Belgium and the Netherlands, also reflects the fact that the marine aggregates resources present in their coastal waters do not include the coarse sands and gravels required to make concrete and concrete products. Consequently, the ability for the sector to maintain its ability to export marine sand and gravel to customers on the near continent has been important, despite the change in trading arrangements. Although there is now additional administration and bureaucracy, initial indications suggest the export tonnages have remained stable following the UK’s formal departure from the EU at the end of 2020.

Whilst Brexit brought a variety of challenges that were reasonably well predicted, the influence of the pandemic resulted in profound and unexpected impacts on society and the wider economy. The marine aggregate sector was not immune from these impacts, with the initial lockdown arrangements in the first half of 2020 resulting in a significant downturn in construction activity, with attendant impacts on the demand for and supply of construction materials. This resulted in several vessels being temporarily stopped between March and May until construction activity picked up. However, when it did resume, aided by government recognizing construction and the supply chain that supports it, as an ‘essential activity’, the pent-up demand meant that production levels in many parts of the country – particularly London and the South East – rapidly returned. This level of recovery in market demand is reflected in the overall landing figures of marine aggregates used for construction in UK, with 12.1 million tonnes during 2020, compared with 13.4 million tonnes in 2019. The introduction of robust Covid-secure working practices, with each ships’ crew being protected as a ‘bubble’ during their three-week trips on board, helped to ensure that Covid-related disruption was minimized.

Climate change

Although Brexit and the pandemic have presented a series of challenges in the short term, arguably the greatest challenge facing society in the medium to long term is climate change. As well as the need to transition towards net zero, there is a growing recognition of the need for widescale adaptation to ensure that society, the economy, and our environment are prepared for the inevitable changes that will result. Alongside the risks posed by sea-level rise, the increased energy contained within a warming atmosphere is already resulting in more extreme weather events.

The effects of these dual influences will be felt along Britain’s coastline, particularly where there are vulnerable communities and infrastructure, or sensitive environments that are unable to respond to the pace of environmental change. For many decades now, marine aggregate resources have played a key role in helping to protect the nation’s coastline by providing sand and gravel to replenish beaches and coastal frontages, and this role is likely to become increasingly important.

Since 1990, more than 30 million tonnes of marine sand and gravel have been used to replenish or nourish areas of coastline around the country, particularly around the North Sea and along the English Channel. Lincshore is the longest-running beach-replenishment project in Britain and has been protecting 24km of the Lincolnshire coastline since nourishment commenced in 1994. In 2021, 700,000 tonnes of marine sand were pumped on to the beach frontage from licence areas off the Humber, helping to protect 30,000 properties and 35km2 of land. At the same time, the enhanced beach frontage helps to support regional tourism and recreation. Similar schemes have taken place along the south coast, at Hythe in Kent, and along the beach frontage at Bournemouth, where more than 500,000 tonnes of sand were delivered between February and March 2021 to complete the works in advance of the summer holiday season.

Whilst these projects rely upon regular campaigns to top-up beach volumes, a very different approach was trialled during 2019 at Bacton, in North Norfolk. Modelled on a Dutch approach termed ‘zandmotor’ or ‘sand engine’, this approach uses the natural forces of wind, waves, and tide to redistribute sand along the coast over many years after a large volume of sediment is added to a coast as a one-off project. Bacton is the location of a major gas terminal which processes up to one third of UK gas demand and, as such, is considered nationally significant infrastructure. However, the terminal is located on a section of eroding coastline, where reduced beach levels had resulted the cliff frontage being eroded with the risk of several of the import pipelines becoming exposed. In 2019, a collaboration between North Norfolk District Council, the Environment Agency, and the operators of the gas terminal (Shell UK Ltd and Perenco UK Ltd), resulted in 3.1 million tonnes of marine sand and gravel from licensed areas off Lowestoft and Great Yarmouth being deposited along the beach frontage from Bacton to the village of Walcott. This had the effect of increasing the height and the width of the beaches, meaning that the energy of waves – particularly during storm events – is absorbed before reaching the cliffs. Over time, the sand is expected to be transported down the coast, helping to reduce erosion and improve flood protection.

These innovative solutions to adapt to the large-scale challenges presented by climate change can only be realized using marine sand and gravels. The ongoing need to protect vulnerable coastlines and the communities, infrastructure, and environmental features they support, reinforces the strategic importance of marine aggregate resources.

Climate change also plays a role in the importance of marine aggregate resources to support construction activity across England and Wales. The ability to transport large volumes of low-cost bulk material over large distances and deliver this into the heart of coastal urban areas, close to the point of demand, remains one of the key strengths of the marine aggregate sector. Wharves along the river Thames landed more than 8.2 million tonnes of marine aggregates during 2021, equivalent to 1,100 lorry loads being delivered every single day of the year. In doing so, this significantly reduces the road miles required to get these essential raw materials to their point of use, reducing emissions and road congestion.

Investment

Recent years have also shown examples of further investment in wharf infrastructure to support more efficient landing and redistribution of marine aggregate materials. In 2019 Peruvian Wharf, located on the north bank of the river Thames in Silvertown, received its first cargo for more than 20 years after being brought back into operation by the Port of London Authority. The site, which is being operated by Brett Aggregates, includes a concrete batching plant and is supplied with processed marine sand and gravel delivered by barge from a marine aggregate wharf at Cliffe on the north Kent coast.

At CEMEX’s Northfleet wharf, on the south bank of the Thames on the Ebbsfleet Peninsula, a new £3.5 million dry discharge system was installed with the support of the Port of London Authority, replacing the previous wet discharge system used at the site. The new system was opened in 2019 and has increased the annual capacity of the site by 70% due to the faster turnaround of the vessels discharging.

The Tilbury2 development, at the Port of Tilbury on the north side of the Thames in Essex, was permitted in 2019 and formally opened by the Prime Minister in January 2022. A £250 million investment by Forth Ports, the new facility includes a construction materials terminal being developed by Tarmac, with deep-water access supported by a bespoke 2km aggregates conveyor system and a railhead capable of taking the longest freight trains. The first trial marine aggregate cargo was delivered in February 2022, and when fully operational the site will allow crushed rock and marine sand and gravel to be delivered to the terminal and processed, before being re-distributed by rail.

On the south coast at Newhaven, in East Sussex, a new marine aggregate terminal was opened in 2020 by Brett Aggregates. Located close to the strategically important marine aggregate resources in the East English Channel, the site is unique on the south coast in that it benefits from a rail link. This allows marine sand and gravel to be transported to London, as well as supporting local construction market demand.

The new Hinkley Point C nuclear power station, which is being built on the coast of Somerset, is one of the largest construction projects in the UK. Its location on the shore of the Bristol Channel provides an opportunity for construction materials to be landed by sea. To enable this, a 500m long jetty has been built which has allowed Hanson to supply crushed rock and marine sand directly to the site by sea, reducing lorry movements, emissions, and disruption to local communities. The recent government commitment to support a further nuclear new build at Sizewell on the Suffolk coast may also provide future opportunities for marine aggregate materials to be used – whether in the construction of the project itself, or in the coastal protection works that will be necessary to ensure the site’s resilience to the effects of sea-level rise and more frequent storm events.

A further example of the potential benefits of employing waterborne transport can be found in the North East. Marine aggregates have historically been landed at various wharves at ports on the river Humber for use by the local construction market. But the reinstatement of a wharf in Leeds, supported by commercial barge transport, saw 400 tonnes of marine sand being delivered to the city in 2021, supplied from AC Marine Aggregates’ wharf in Hull – the first commercial freight that had come into Leeds by barge for 19 years.

The variety of demands that exist across these very different markets means that marine aggregate operators need flexibility to adapt to changing market conditions. Although the licensed reserves may be in fixed geographical locations, the fleet of dredging vessels is able to relocate to match production capacity with market demand. But it is also clear that the wharves and transport infrastructures that support these are also evolving and, consequently, it is important that the strategic importance of not only the marine aggregate resources, but also the wharves that facilitate their ability to access the market, is properly recognized.

Planning policy

In late 2021, the remaining English marine plans were formally adopted, comprising the North West, South East (Outer Thames), South West, and North West. These joined the East (southern North Sea) and South (English Channel) plans adopted some time ago. The marine aggregate sector’s engagement with the plan development process ensured that the infrastructure policies in each new plan explicitly recognize the need to safeguard minerals landing facilities in accordance with National Planning Policy Framework (NPPF) and reference the agent of change provision established in national policy.

The marine aggregate policies contained within each marine plan look to safeguard licence/application/option areas and areas of high resource potential, and the narrative supporting this links to both the NPPF and the UK Marine Policy Statement, again because of the evidence submitted by the sector.

All English marine plans now consistently recognize the role and contribution of marine aggregates – both for construction and for coastal defence – and have policies in place to safeguard marine aggregate resources and landing infrastructure in accordance with national policy.

Policies and plans that safeguard resources and the landing facilities to access the market provide much needed confidence to the marine aggregate industry. While the investment in wharves provides one example of this, a more visible indicator is the two brand-new purpose-built marine aggregate dredgers that entered service in 2021 (CEMEX Go Innovation) and 2022 (Hanson Thames). Representing a collective investment of around £70 million, these vessels are the first examples of a new Marine Aggregate Dredger (MAD) 3500 class, designed and built by Damen Shipyards in their Galati shipyard in Romania. Whilst similar in size to twentieth-century equivalents, the MAD 3500 is a completely new class that is said to represent a ‘quantum leap’ forward in terms of both the quantity of product it can carry (20% more) and its operational cost per tonne, thanks to the latest fuel-efficient propulsion systems and the ability to conduct operations while running on a single engine.

Although the last three years have presented a range of challenges that have had to be negotiated and overcome by the British marine aggregate sector, it now finds itself in a far stronger position to navigate a course forward.

- Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com