The Emerald Challenge

First published in the April 2024 issue of Quarry Management

IQ’s £5,000 Emerald Challenge returns to echo first year’s success

The Institute of Quarrying (IQ) is inviting applications from professionals working in the mineral products sector to secure a £5,000 financial grant. For the second year in a row, IQ is running The Emerald Challenge, which was launched to support the industry in achieving its net-zero carbon and sustainability ambitions.

The Emerald Challenge aims to support and recognize IQ members as they develop projects and research ideas to help their organizations and the wider industry meet climate challenges. It is open to IQ technical members (TMIQ), members (MIQ) and fellows (FIQ) and is a fantastic opportunity to seek funding to develop ideas that directly contribute to the progress of an organization towards meeting global climate challenges.

IQ chief executive officer James Thorne explained: ‘It is important to us as a leading sector organization to contribute to the essential sustainability and decarbonizing solutions that will put the UK on track to meeting its objective to be Net Zero Carbon by 2050, in line with the COP27 agreement and the UN Sustainable Development Goals.

‘It’s a fantastic opportunity for members to get involved if they have research ideas and sustainability projects covering topic areas such as decarbonization, energy efficiency, materials efficiency/circular economy, biodiversity and habitat improvement, pollution control/mitigation, and water management.’

Amongst the judging panel for The Emerald Challenge submissions sits the IQ President, IQ Chair, IQ CEO, representatives from the board of trustees and council, and a representative of the IQ’s Education and Training team.

The winning submission is set to be announced at the IQ’s annual Fellows’ Lunch and Student Awards event in London, in October 2024, where the winner will be recognized for their achievement and presented with an award in person.

This year’s deadline for application submissions is Friday 28 June 2024.

Inspiring and transformative winners

Last year’s inaugural Emerald Challenge received a wealth of innovative entries, resulting in two exciting projects being awarded the prize. Since winning, both projects have blossomed, progressing into being recognized as game-changers in their impacts.

2023 Winner – Andrew Gall, Forestry and Land Scotland (FLS)

‘Pollution control and water management’

Andrew Gall, quarry manager working with Forestry and Land Scotland, entered The Emerald Challenge to explore a compelling idea of his. The vision was to create an environmentally friendly and cost-effective solution for managing silt during timber haulage road construction projects, initially in Scotland’s Central region and potentially, internationally.

Andrew says: ‘I had the idea for some time but no way of bringing it to fruition. When I heard I had won The Emerald Challenge I really had to compose myself, because it really did give me a transformative opportunity to test my idea and try to make it a viable solution.’

On average, 30km of new timber haulage road construction takes place every year within the Central Belt of Scotland. A major part of those works includes ‘water management’, runoff, defuse pollution, and ditching works.

Andrew’s vision was to revolutionize current silt-management methodologies and provide a low-cost and effective barrier that is easily accessible, recyclable in nature, affordable, and fit for purpose. This would replace the use of harsher and more expensive materials currently deployed, as well as the need for repetitive maintenance.

Its performance would be judged and monitored using simple water contamination test kits such as Watersafe provided by SimplexHealth, the result being that water runoff from quarrying works and road construction works should be safe to drink at source.

Extensive research conducted by Andrew, including during a very wet February, confirmed that his ingenious filtration silt sump idea works. As a result, scale-up investment interest has followed from both civil engineers and ecologists in Scotland for wind farms and other projects, having been impressed not only by its performance and re-use functionality, but also by its ease of installation.

‘Without The Emerald Challenge, my idea would have remained as nothing more. By winning I got the impetus and confidence to do something I passionately believed in and make a success of it. An incredible year, with the best still to come, thanks to The Emerald Challenge,’ adds Andrew.

2023 Winners – Oliver Kibble, Tarmac; and Thomas Clifford, GEARS

‘Blasting down CO2 emissions’

A joint project between Tarmac and GEARS, this Emerald Challenge submission focused on reducing CO2 emissions in hard rock quarries through enhanced blast fragmentation. The methodology involved the purchase and installation of necessary equipment for baseline data collection, analysis, and reporting. Objectives included measuring various parameters during a baseline blast, measuring the secondary breakage on site, designing a new blast for improved fragmentation, and then re-measuring the parameters from the improved blast.

Oliver and Thomas knew the potential industry-wide impact of the project in reducing emissions and achieving cost savings. ‘The project provided the perfect opportunity to re-think the CO2 emissions created because of blasting operations. The platform and support provided by The Emerald Challenge Award, plus Tarmac and GEARS’ collaboration, has fast-tracked and enriched the project,’ says Oliver.

Research and apprentice development

It is clear that the project has made fantastic progress, including Tarmac selecting one of their flagship quarries as the test site for the ongoing project.

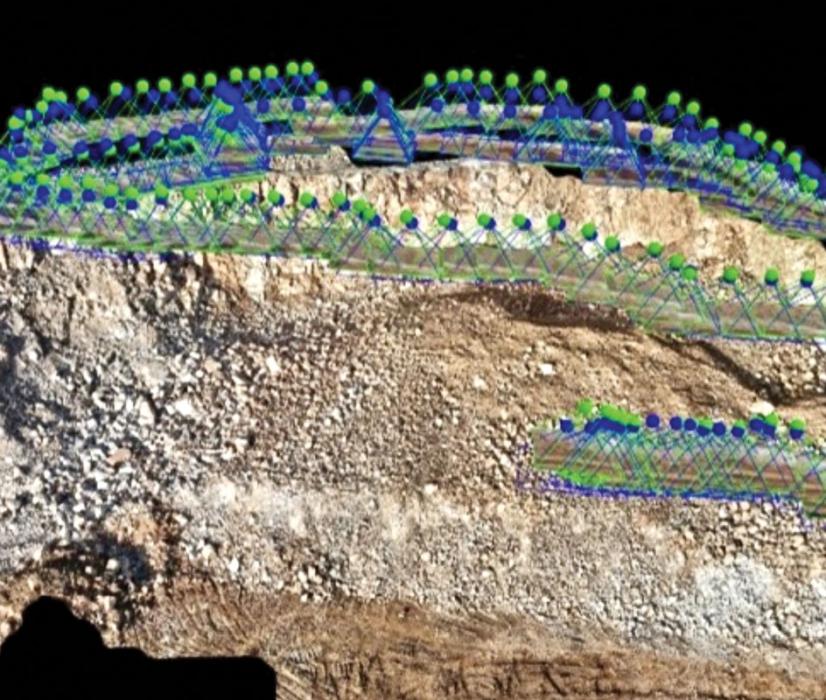

There have been unexpected people benefits too. Importantly, as part of the project prize money, GEARS have been able to train Oliver Kibble and quarry manager Aaron Laycock, along with two of Tarmac’s Higher Apprentices, Rajen Gupta and Mustafa Malek, to undertake face and blast pile drone surveys to support the fragmentation analysis of the blast piles and data collection. This footage is processed using the FragMAP software developed by GEARS to determine how well each blast has fragmented the rock. Both Rajen and Mustafa are completing their Foundation Degrees at Derby University and will aim to apply their learning as part of the project.

‘To be part of an opportunity such as this, addressing important net-zero challenges, is very valuable to me as part of my apprenticeship learning,’ says Rajen Gupta. Mustafa Malek adds: ‘I’ve completed my first 3D model of a blast pile thanks to it. To be actively involved in new research like this and to gain new skills is so satisfying.’

A project gaining traction

The project is also using bespoke digital technology, developed by GEARS, which is being deployed via their AggCAM cloud-based grading tool. The AggCAM uses ‘GoPro’ type cameras with an artificial intelligence (AI) software program that provides a dashboard for quarry management and plant operators to visually demonstrate the particle size distribution of the aggregate going through the processing plant by taking photographs every five seconds.

The AggCAM camera was installed on the first conveyor belt after the primary crusher. This monitors the fragmentation with data captured continuously throughout the day. The AI and machine learning software is utilized to calculate the fragmentation sizes of the rock on the conveyor belt. The accuracy of AggCAM will allow Tarmac to optimize blasting on site, to ensure the desired fragmentation is achieved.

‘In addition to the fragmentation being monitored, we are collecting additional data throughout the operational process. This includes electricity consumption of the primary crushing plant, telematic data of the mobile plant on site, and any secondary ™۔ breakage that is being undertaken each day,’ adds Oliver.

The project has also monitored the impact on fragmentation when the burden and spacing for each blast design is altered to determine the optimum blast design. If the burden and spacing is optimized less oversized material is produced. This, in turn, reduces the need for secondary breakage, reduces blockages, and increases the plant throughput and cycle times.

The next stage of the project will be to convert the energy consumption to CO2 emissions for the quarry, to determine the potential CO2 and cost savings by improving the blast fragmentation.

‘The Emerald Challenge inspired us to present the idea and winning it inspired the management teams to get behind and support the research. By the end of 2024 we hope to be able to share data on the CO2 emissions,’ says Oliver.

Meeting industry and national sustainability goals

As last year’s winners prove, The Emerald Challenge is both relevant and valuable. Already, it has provided a catalyst to address two tangible and far-reaching challenges within the sector.

Steve Cole is a member of the IQ Council and as founder of The Emerald Challenge is responsible for the original idea and concept. He says: ‘It’s so rewarding to witness the projects flourish after winning The Emerald Challenge. The judging panel saw their potential, but the results are exceeding our expectations. It’s abundantly evident that there’s a collective passion for fostering ideas aimed at safeguarding our environment, aligning perfectly with the UK’s Sustainable Development Goals.’

Viv Russell, IQ President, adds: ‘I was delighted with the quantity, quality, and diversity of entries for last year’s Emerald Challenge. It made the judging process challenging when narrowing down the applicants, but it was a pleasure to receive so many ambitious projects submitted from a range of individuals who clearly share a passion for improving the industry’s sustainability efforts. I am very much looking forward to seeing this year’s entrants for their ingenuity combined with professional knowledge to tackle key issues.’

Information about The Emerald Challenge, how to apply, what sort of projects can be submitted, topic areas, who is eligible, and important dates are available online at: www.quarrying.org/emerald-challenge. Contact Sarah Fry (sarah.fry@quarrying.org) for additional enquiries.

Subscribe to Quarry Management, the monthly journal for the mineral products industry, to read articles before they appear on Agg-Net.com