Versatile new milling technology from IIT

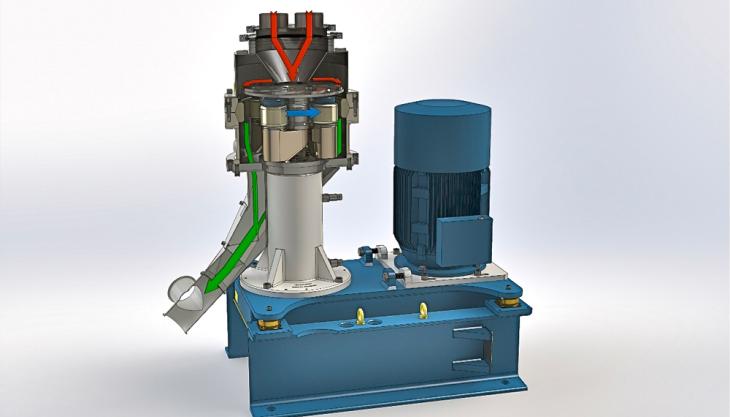

Company extends ‘m-series’ vertical roller mill range with launch of new M350 system

UK-based International Innovative Milling Technologies Ltd (IIT) have developed a new low-energy milling solution for a wide range of powder processing applications. The innovative new M350 milling system extends the company’s ‘m-series’ range of vertical roller mills and is a direct outcome of the company’s involvement in the Project Chariot powder-manufacturing programme.

This three-year collaborative project, headed by Procter & Gamble’s Technical Centre as part of the UK Government’s Advanced Manufacturing Supply Chain Initiative (AMSCI), was involved with the development of new technologies for advanced powder handling and processing applications.

IIT’s new M350 mill is specifically designed to accommodate an output capacity range of up to 4.5 tonnes/h for single-pass applications and 500kg/h for finer products requiring classification. In this way, the mill provides a versatile and flexible solution for the effective size reduction of a wide range of bulk materials across the complete scale of hardness up to 9.5 Mohs.

As such, the M350 is suitable for the processing of a wide range of minerals and other industrial products, including glass, sodium bicarbonate, iron slag, sodium sulphate, limestone‚ zircon sand, silica sand, pet-coke, fly ash and different types of blast-furnace slag.

The design of the ATEX-compliant mill is based on a patented centrifugal grinding mechanism, utilizing a special pivoting roller assembly and a static grinding ring to provide a highly energy-efficient size-reduction capability.

The modular assembly of the M350 is also designed for efficient strip-down, cleaning and maintenance, and includes a variety of construction material options to suit specific markets and applications.

The design also minimizes induced airflow through the mill, thereby reducing the ancillary equipment requirements often associated with similar mills and making the complete installation significantly smaller.

These features, together with a non-captive bed, a profiled spreader plate and other design innovations, means that the size of the milled product remains consistent. In addition, accurate control of particle size distribution changes can be achieved by smooth operating adjustments to the rotational speed of the mill – providing effective ‘one-pass’ milling if required.

For speed of installation, the low-mass mill and its associated control system package are mounted on sub-frame assemblies that can be easily transported between different process locations for maximum feedstock and operational versatility.

As a result, the ergonomically designed mill can be utilized for a range of powder processing applications, including process validation, batch processing, research and development, material preparation and pre-processing routines.

For fully integrated powder milling processing solutions, IIT also offer complementary ‘c-series’ classifiers and ‘s-series’ cyclones.