Technidrive boost efficiency and cut costs in conveyor applications

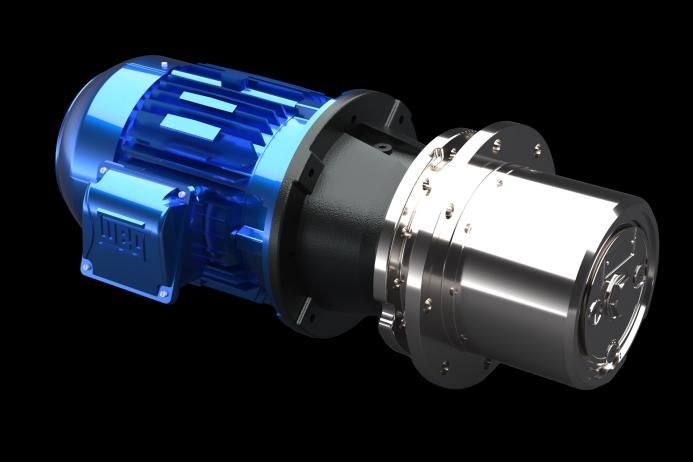

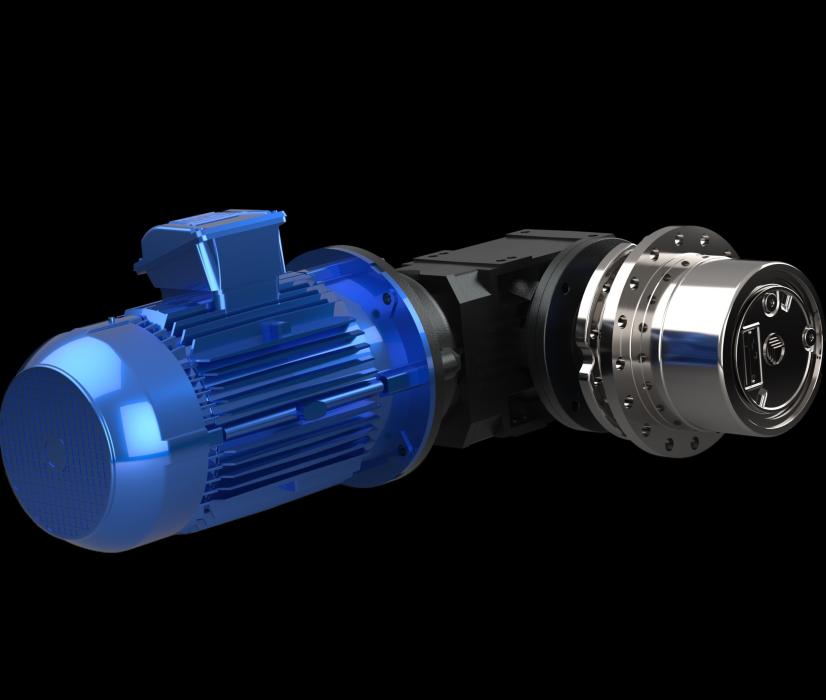

Drum Drive electric motor and gearbox unit supports quarries and recycling facilities on path to electrification

TECHNIDRIVE, bespoke electric motor and gearbox providers, have developed a drive solution for heavy-duty conveyors that minimizes costs while maximizing efficiency and uptime. The Drum Drive reduces the total cost of ownership by up to a third compared with conventional bevel helical gearbox units for quarrying and recycling applications.

Industries such as quarrying and recycling are evolving in response to climate change and soaring energy costs. McKinsey estimate that the mining sector needs to reduce emissions by 85% by 2050. Switching to mobile electrified equipment such as conveyors while optimizing energy efficiency is core to this transition.

Electric conveyors tend to be larger and heavier than comparable hydraulic equipment, meaning that space and weight come at a premium. Consequently, there is growing demand for compact electric motor and gearbox solutions that minimize footprint and weight while maximizing energy efficiency. The Drum Drive meets this demand.

The Drum Drive is a compact track drive gearbox with 53% less mass than a typical bevel helical gearbox unit with the same power, torque, and speed.

Thanks to its reduced size and weight, the Drum Drive, unlike helical gearboxes, can be installed directly inside a conveyor head drum. As the unit acts as a bearing, it eliminates the need for shaft and bearings requiring regular lubrication. Fewer parts translate into lower upfront costs, reduced maintenance, and extended lifespan. The Drum Drive also achieves a 20% higher service factor and 60% higher shaft radial load ratings.

Oil seals in helical gearboxes are a frequent cause of failure in arduous environments such as quarries and recycling plants due to exposure to dust and water. The Drum Drive eliminates this problem thanks to fully enclosed oil seals.

Another core benefit of the Drum Drive is its high-efficiency motor technology from WEG. The drive can be fitted with the latest permanent magnet (PM) motors or hybrid motors integrating PM, ferrite, or neodymium magnets, along with synchronous reluctance (SynRM) technologies.

Initially developed for low-speed, high-torque feeders, the Drum Drive range has been expanded to suit high-speed, low-torque conveyors with higher power ratio requirements, thanks to the integration of motors with a higher power ratio in a smaller frame.

‘Industries like quarrying and recycling are evolving to reduce emissions in line with global climate targets while also optimizing uptime to meet the growing demand for raw materials and keeping costs in check,’ said David Strain, technical director at Technidrive.

‘Our extensive experience in drive solutions combined with the latest gearbox and motor technology enables us to support our customers on their path towards electrification, helping them take efficiency and reliability to the next level with a reduced total cost of ownership.