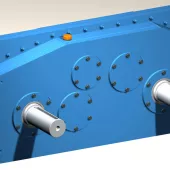

Renold SH sprag clutch holdbacks

Heavy-duty backstop series provides effective safety solution for inclined conveyors and bucket elevators

RENOLD Clutches & Couplings’ SH series of sprag clutch holdbacks with central torque arm offer an effective solution for arduous, heavy-duty applications such as inclined belt conveyors and bucket elevators where reverse running due to loss of drive could have catastrophic consequences. If drive is lost, the SH sprag clutch holdback instantaneously prevents any runback.

Inclined conveyors are commonly found at mines, quarries and cement works. Many of them are of considerable length and the weight of material on them at any one time can be enormous. If the drive stalls and the conveyor back-drives, it will accelerate due to gravity until all the load on the conveyor has been dumped at the bottom.

If a fully loaded inclined conveyor runs backwards it will tend to run much faster than it runs forward. While this is not a problem for the conveyor and the bearings, it can be catastrophic for the components on the other side of the gearbox. The out-of-control conveyor would drive the gearbox the wrong way, changing its speed-reducing role to one of a speed amplifier.

This would overload components in the drivetrain that would have been sized for normal operating conditions when the conveyor runs forward. If a fluid coupling is fitted, to provide a soft start for the conveyor, its aluminium casing would be put under massive centrifugal loads, with the potential to explode like a bomb, spreading shrapnel and hot hydraulic oil across the site.

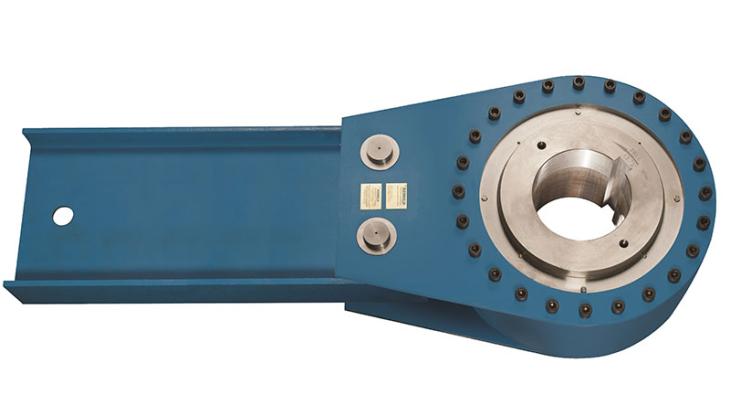

To prevent this from happening, a Renold SH sprag clutch holdback is positioned on the end of the conveyor headshaft. If the drive fails or is stopped when the conveyor is loaded, the high-quality sprag elements of the clutch, which are in constant contact at all times with the inner and outer races of the clutch element of the holdback, instantaneously prevent any runback, thereby preventing any damage to plant and equipment, eliminating the resultant downtime that would follow, and removing any potential accident risk to personnel.

Renold SH sprag clutch holdbacks are suitable for applications such as inclined conveyors in mining, quarrying and materials handling, and on apron feeders in mining applications. Featuring high-quality components for long unit life and low operating costs, they are able to accommodate large bores of up to 20in and have a high torque capacity within a compact design. Moreover, the dimensionally interchangeable one-piece central torque arm is designed for ease of replacement against other brands.