Niche processing capability fills gap in market

Staffs Powder Processing addressing growing UK demand for material agglomeration and pelletization

STAFFS Powder Processing Ltd (SPP) are a family-owned and operated business based in Stoke-on-Trent, Staffordshire, who are aiming to fill a gap in the UK market for material agglomeration and niche processing.

Founded in early 2013 by brothers Matthew and James Evans, who between them have 30 years’ experience of mineral and chemical processing, the company has invested heavily in new production equipment, including crushers, dryers, kilns, agglomeration mixers and laboratory equipment, as it continues to grow in the UK.

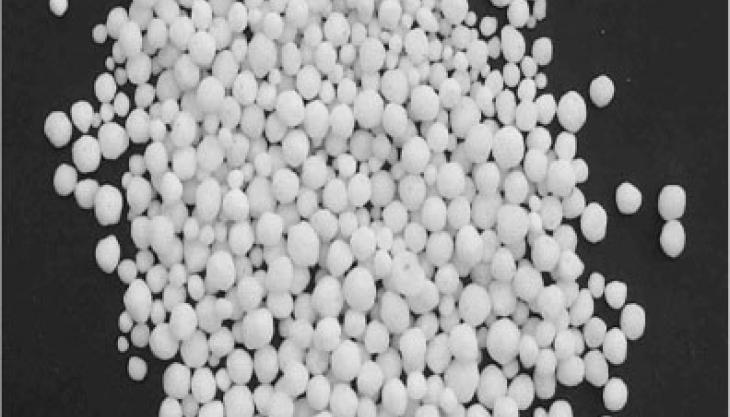

Prior to the formation of SPP, the Evans brothers worked for the family business which focused on the manufacture and supply of chemicals and minerals to the heavy clay industry. The creation of SPP marked a step into the processing side of the industry with the aim of providing a much sought after service – the pelletizing and agglomeration of powdered materials.

According to Matthew Evans, there was a need for a company able to offer development and feasibility studies for those wishing to commercialize large-scale pellet production plants, which led to the installation of a pilot-scale pelletizing plant capable of producing several tonnes of product per day.

Following on from this the company has successfully developed and manufactured a wide range of pelletized products for the ceramic, catalyst, mining, agro-chemical, and waste industries.

According to SPP, what sets them apart from other manufacturers is their flexible approach, knowledge and willingness to adapt plant and machinery, which is why the company offers both part and complete hire and use of its vast inventory of equipment.

‘We see an increasing demand for the pelletization of dusty or problematic materials, not just because of health and safety issues, but also because of the need for free-flowing end products, which is why we are continuing to invest in specialist pelletizing technology,’ explained James Evans.

In addition to testing and feasibility studies, the company also has the ability and resources to handle many different liquid and powdered chemicals and minerals, and routinely toll processes materials for large multinational companies. This includes drying, milling, blending, sieving, crushing, calcination, and pan granulation, or combinations of these processes.

In particular, the company specializes in two very niche processing areas – bespoke catalyst formulation and the agglomeration of powders. ‘We found that there was a distinct lack of UK companies able to design and manufacture transition metal oxide catalysts, and because of this we have developed a unique and cost-effective method from formulation through to production,’ said Matthew Evans.

He continued: ‘There are only a handful of companies in the UK that can pelletize a product, and of these very few will process outside work. SPP are actively seeking long-term processing partnerships with minerals and mining companies worldwide. In particular, we are currently developing a waste-derived synthetic fracking sand and are looking for partners to move this project forward.’